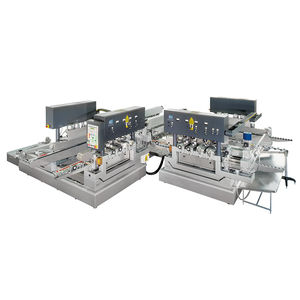

Straight edges grinding machine FLEX-Edgeflatglassautomatic

Add to favorites

Compare this product

Characteristics

- Type

- flat

- Applications

- glass

- Control type

- automatic

- Other characteristics

- precision, straight edges

Description

Bottero machines are ideal for processing structural glass, partition walls, shower cubicles, shelves, balustrades, steps and furnishing elements, providing productivity, precision and reliability over time to operate on multiple shifts, up to 24/7 service.

The Bottero range of double edgers for flat edge processing has been designed to meet all requirements of performance and quality.

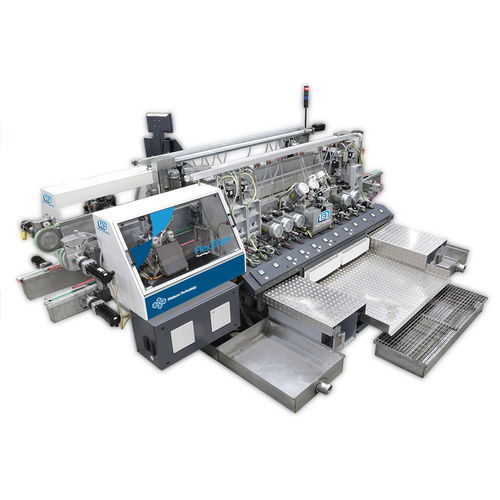

The new automatic dubbing facility enables the finished pieces to be transferred immediately to the toughening process. The dubbed corners are also safer to handle. In the double edger model the finishing unit can be: • Pneumatic (standard model): manual tracking speed adjustment and manual edge dimension adjustment (without changing the size of the wheel). • Servo-Pneumatic: manual tracking speed adjustment and motorised edge dimension adjustment from control panel (without changing the size of the wheel).

Fully servo for radius and chamfers: motorized tracking speed adjustment and motorised edge dimension adjustment from control panel (without changing the size of the wheel) Including double grinding tools (diamond & polishing). The high quality of the polishing is guaranteed by the automatic control of the pressure of the proportional valves (Patent Pending). - maximum radius 5 mm regardless of the glass thickness - maximum working speed with polished finishing 3 m/min - maximum chamfer 7 mm - maximum glass thickness 30 mm

Catalogs

Flat Glass General Catalogue

49 Pages

Double Edgers Flat edge

21 Pages

Related Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Beveling machine

- Flat grinding machine

- Electric beveling machine

- High-precision grinding machine

- Automated grinding machine

- Vertical grinding machine

- Edge beveling machine

- Glass grinding machine

- Double grinding machine

- Straight edges grinding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.