- Production Machines

- Other Manufacturing Equipment

- Tunnel demagnetizer

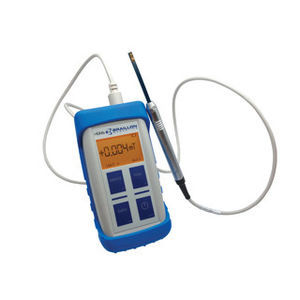

- Braillon Magnetics

Tunnel demagnetizer 16.05.Bfor workpiecesconveyor belt

Add to favorites

Compare this product

Characteristics

- Configuration

- tunnel

- Product handled

- for workpieces

- Other characteristics

- conveyor belt

Description

Tunnel demagnetizer fully integrated in the conveyor belt

High performance resin encapsulated coil (black)

Reinforced system

Aluminium frame

Conveyor with fairing, with tunnel integration

On/off switch with pilot light

Thermal circuit breaker

Electrical box

A part to be demagnetised must be exposed to an alternating magnetic field which reduces H. In order to demagnetise these parts, either to comply with a specification (automotive standards, etc.) or to carry out machining (on a wire machine, for example), the part is passed through the tunnel at a slow and constant speed (approximately 0.2 m/sec). It is essential to take the workpiece out of the demagnetiser by 40 to 60 cm before switching it off. Demagnetisation test possible. Ask your technical advisor.

Use :Demagnetization

Voltage :220/400/480 VACDuty cycle :100 %

Options :

Other transport belt with grip

Starter box with workpiece position sensor

Automatic machine for multiple demagnetizing passes

Frequency converter for demagnetising parts that are difficult to demagnetise

Can be supplied with robot cell interface: on request, to be defined with the application

VIDEO

Catalogs

No catalogs are available for this product.

See all of Braillon Magnetics‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.