- Products

- Catalogs

- News & Trends

- Exhibitions

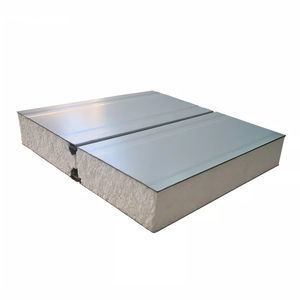

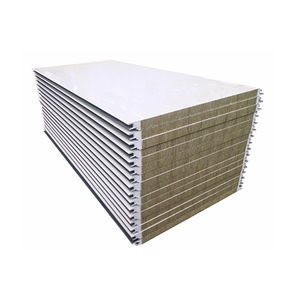

Mineral wool core sandwich panel rock wool coresteel facingwith stainless steel facing

Add to favorites

Compare this product

Characteristics

- Core

- mineral wool core, rock wool core

- Facing

- steel facing, with stainless steel facing

- Other characteristics

- thermal

- Thickness

Max.: 200 mm

(7.874 in)Min.: 50 mm

(1.969 in)- Width

Max.: 1,150 mm

(45.28 in)Min.: 500 mm

(19.69 in)- Thermal conductivity

0.022 W/(m.K)

Description

Rock Mineral Wool Cold Room Panels is composed of two galvanized stee sheets and rigid rock mineral wool foam in the middle. It has been widely used as the building material of cold storages, cool rooms, clean rooms, free-dust workshops and exterior walls in cold places.The rock mineral wool sandwich panel is made of basalt and other natural ores as the main raw materials. The rock wool board is melted into fiber at high temperature, added with an appropriate amount of binder, and solidified. rock mineral wool sandwich panel products are suitable for thermal insulation and sound insulation of industrial equipment, buildings and ships.

Rock Mineral Wool insulation core

Good heat insultion performence

Vertical or horizontal installation

Cold Room Panels are composed of 3 layers, the external and internal is galvanized sheet or Aluminum sheets, and core materials used high density rock mineral wool foam. Thanks to their good thermal insulation properties, it can be applied in projects that required very high heat insulation performanece, like cold storage, cool room ,freezer, refrigerating workshop construction.

Feature:

▲Energy saving

▲Thermal insulation

▲Design flexibility

▲Aesthetically pleasing

▲Meets health industry regulations

★Cool Rooms

★Freezers Rooms

★Dual Temperature Rooms

★Laboratories cold rooms

★Proven rooms

★Cold Storage Facilities

★Warm rooms

1, First of all, it must carry on the construction preparation before installation, include personnel, materials, etc. All will be well prepared.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.