- Products

- Catalogs

- News & Trends

- Exhibitions

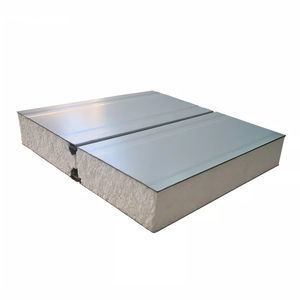

Mineral wool core sandwich panel rock wool coresteel facingwall

Add to favorites

Compare this product

Characteristics

- Core

- mineral wool core, rock wool core

- Facing

- steel facing

- Applications

- wall

- Other characteristics

- thermal

- Thickness

Max.: 200 mm

(7.874 in)Min.: 50 mm

(1.969 in)- Width

1,000 mm

(39.37 in)- Thermal conductivity

0.023 W/(m.K)

Description

The rock mineral wool sandwich panel is made of basalt and other natural ores as the main raw materials. The rock wool board is melted into fiber at high temperature, added with an appropriate amount of binder, and solidified. rock mineral wool sandwich panel products are suitable for thermal insulation and sound insulation of industrial equipment, buildings and ships.

The coefficient of thermal conductivity is 0.023w/(m.k), which ensures better thermal insulation efficiency. In practice, this effectively keeps the building absorbing heat and brings enormous economic benefits.

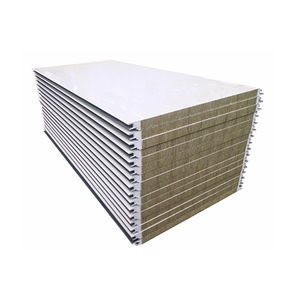

PU Sandwich Panels are composed of 3 layers, the external and internal is two dyed Galvanized or Aluminum corrugated plates, and core Polyurethane (PU) rigid foam. Due to the advantages as heat and sound insulation, high load capacity, light weight (about 10kg/m2), quick movement and easy to install, PU Sandwich Panel are procured with the best prices and used in the buildings whose load-bearing system is of steel and prefabricated concrete, such as industrial buildings, military buildings, social buildings, agricultural buildings, sports facilities, construction sites, silos, hypermarkets, shopping malls, cold storage depots and marketplaces. The products to meet the requirements of any kind of architectural project are produced with aluminum or dyed galvanized sheet metals, in requested amounts and dimensions at BRD Sandwich Panel.

PU sandwich panels are applied as external walls and internal division walls, installed vertically or horizontally on single- or multi-span structure. Thanks to its hidden joint the panel ensures very aesthetic look of the wall or façade.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.