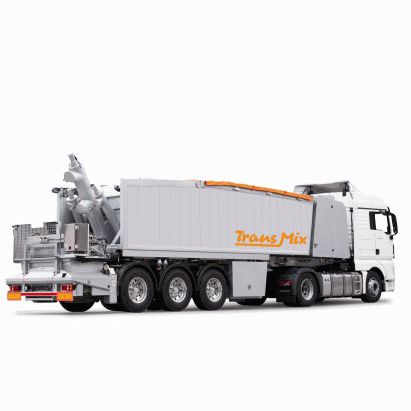

The TransMix 3200 FE-ST is a mobile logistics system for the processing of polystyrene insulation in the form of bundled fills, which significantly reduces the costs for personnel and materials, as well as the general logistics costs such as tooling times and material losses.

The TransMix systems have everything on board that is needed to manufacture screed or polystyrene insulation. The division of the basin into 4 chambers for the various materials is a fundamental characteristic and is designed depending on customer requirements.

The basin is tilted upwards on the construction site using hydraulics, whereby the aggregates and binding agents automatically reach a metering screw. The additive is added using a metering pump. Using these internal conveying systems all materials are transported to the rear of the machine where an integrated weighing device ensures precise metering.

The precisely metered material is conveyed to the mixer and the amount of water required is automatically added. In the mixer of the TransMix 3200 FE polystyrene the insulating material is mixed and then pumped to the placement site.

The time factor plays a significant role on every construction site. Here the TransMix 3200 scores well with an auger pump installed at the rear which conveys up to 18 m3/h.

The TransMix is driven via the power pack which sits directly behind the driver's cab. It contains the drive motor, fuel tank, alternator, variable displacement pump and hose drum. The operation is effected via a central control cabinet which is mounted at the rear. The exact mixing ratio can be entered via the control system and recurring "formulas" stored.