- Detection - Measurement

- Flow, Pressure and Level Measurements

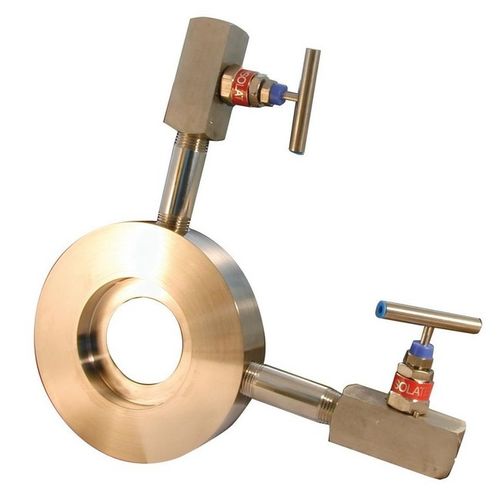

- Orifice plate

- British Rototherm Co. Ltd

Differential pressure flow measurement orifice plate

Add to favorites

Compare this product

Characteristics

- Options

- differential pressure flow measurement

Description

• Design to BS EN ISO 5167

• Range of Carrier Types

- Single Ring, Corner Tappings

- Double Ring, Flange Tappings

- Double Ring, Corner Tappings

- Double Ring, Annular Chambers

• Wide range of materials

• Proven technology

• Suitable for 1” lines and above

• Orifice sizing on request

The orifice plate is the most common differential pressure flow primary element. It is based on proven technology, has no moving parts and is suitable for high temperature and pressure applications. Orifice plates are recommended for clean liquids, gases and low velocity steam flows.

Flow measurement using orifice plates requires the accurate location of upstream and downstream pressure tappings.

Various types of orifice carrier assemblies are available to suit a wide range of applications.

Orifice flange assemblies in accordance with ANSI B16.36 are also available.

Catalogs

No catalogs are available for this product.

See all of British Rototherm Co. Ltd‘s catalogsOther British Rototherm Co. Ltd products

Flow Measurement & Restriction

Related Searches

- Flowmeter

- Volume flowmeter

- Liquid flowmeter

- Pressure gauge

- Level limit switch

- Liquid level limit switch

- Stainless steel flowmeter

- Analog pressure indicator

- Pressure switch

- Mechanical pressure switch

- In-line flowmeter

- Float level switch

- Stainless steel pressure indicator

- Dial pressure indicator

- Threaded pressure indicator

- Stainless steel level limit switch

- Waterproof pressure switch

- Process pressure indicator

- Bourdon tube pressure gauge

- Waterproof pressure gauge

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.