Franklin tester tester FT 600insulation resistancefor electrical appliancesfor coating

Add to favorites

Compare this product

Characteristics

- Test type

- insulation resistance, Franklin tester

- Tested product

- for electrical appliances, for coating, parts

- Applications

- industrial

Description

• Surface resistance

• Resistance distribution

• Coating thickness (optional)

• Determination of surface resistance of individual samples of electrical steel and punched parts

• Quality control of insulation coating

• Manually operated or fully automatic version

• Preparation and execution of the measuring process according to ASTM-standard A 717-81

and IEC 60404-11

Operating principle

Measuring the total current which flows along the insulation coating of the sample when pressure is applied via several contacts. Conversion of the measured value to an equivalent surface resistance. Suitable especially for quality control of insulation coating.

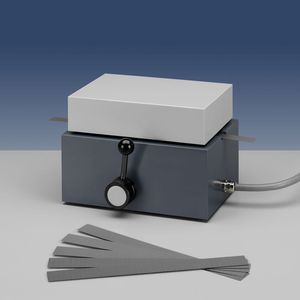

Constructed from 2 main components:

• Voltage supply unit

• Testing device with hydraulic pump

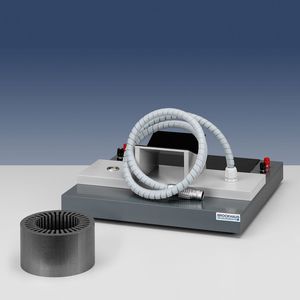

The test head consists of two longitudinal rows of five vertically mounted steel rods which are free to move axially against the surrounding spiral springs. A stainless steel measuring contact is positioned at each end of each rod. It is possible to move the test head hydraulically perpendicular to a surface.

The testing contacts are pressed onto the insulation coating with a pressure of 129N per electrode. An electrical contact to the steel sheet is created with a spiral drill. If the resistance is finite a current proportional to the resistance flows through the insulation coating.

VIDEO

Catalogs

Related Searches

- Test machine

- Measuring device

- Measuring machine

- Test stand

- Material testing machine

- Automatic test machine

- Industrial test machine

- Digital measuring device

- Digital testing system

- Thickness measuring machine

- Automatic test equipment

- Industrial testing system

- Precision test machine

- Optical measuring machine

- Automatic measuring machine

- Automatic testing system

- Industrial gauge

- Industrial test equipment

- Test set

- Measuring system for industrial applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.