- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

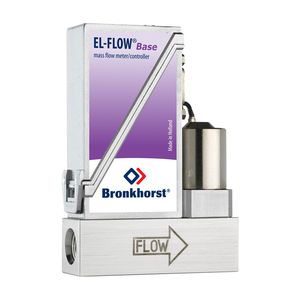

Thermal mass flow meter F-1 seriesturbinevortexdifferential pressure

Add to favorites

Compare this product

Characteristics

- Technology

- thermal mass, turbine, vortex, differential pressure

- Type

- mass

- Fluid

- for gas

- Installation

- in-line

- Communication

- Modbus RTU, PROFIBUS DP, Ethernet

- Protection level

- rugged, IP65

- Applications

- for high flow rates

- Other characteristics

- compact, with mass flow controller, IEC

- Volumetric flow rate

Max.: 11,000 m³/h

(388,461.3339 ft³/h)Min.: 0.4 m³/h

(14.1259 ft³/h)- Process temperature

Max.: 70 °C

(158 °F)Min.: -10 °C

(14 °F)- Process pressure

40 bar, 64 bar, 100 bar, 200 bar, 400 bar

(580.15 psi, 928.24 psi, 1,450.38 psi, 2,900.75 psi, 5,801.51 psi)- Precision

0.1 %, 0.2 %, 0.5 %, 0.8 %, 2 %

- Repeatibility

0.2 %

Description

IN-FLOW Series Thermal Mass Flow Meters for high flow rates of clean gases are equipped with a 'industrial style' pc-board housing offering IP65 protection. Control valves can either be integrally or separately mounted, to measure and control gas flows.

General features

Rugged, weatherproof housing (IP65, dust and waterproof)

Option: FM approval Class I, Div. 2 (Groups A, B, C, D; T4)

Option: KCs certificate (Protection Ex nA IIC T4)

No moving parts

Best in class mean-time-between-failure (MTBF) data based on the IEC 61508 standard

Compact and competitive Mass Flow Meters for high gas flow rates

For consumption measurement of high gas flow rates, customers often select volumetric flow meters e.g. Vortex flow meters, turbine flow meters or instruments based on the measurement of differential pressure. To read mass flow, all these measurement principles require temperature and pressure compensation. Bronkhorst Series F-106 / F-107 directly measure high mass flow rates of gases up to a pipe size of 10 inch / DN 250. Furthermore their digital pc-board offers counter and alarm functions as a standard feature, as well as the option to integrate an on-board interface board for CANopen®, DeviceNet™, EtherCAT®, PROFIBUS DP, PROFINET, Modbus RTU, ASCII or TCP/IP, EtherNet/IP, POWERLINK or FLOW-BUS communication.

Applications

IN-FLOW Series Thermal Mass Flow Meters and Controllers for high flow rates are applied for:

Process gas measurement and control in food industry, chemical and petrochemical industries, in fermentation installations and in biotechnology

Gas consumption measurement for internal accounting

Hydrogen techniques

VIDEO

Catalogs

No catalogs are available for this product.

See all of Bronkhorst‘s catalogsRelated Searches

- Bronkhorst flow meter

- Volume flowmeter

- Bronkhorst liquid flow meter

- Bronkhorst gas flow meter

- Bronkhorst stainless steel flow meter

- Bronkhorst waterproof flow meter

- Bronkhorst industrial flow meter

- Bronkhorst in-line flow meter

- Precision flowmeter

- Bronkhorst compact flow meter

- Water flowmeter

- Bronkhorst DC flow meter

- Bronkhorst mass flow meter

- RS485 flowmeter

- Flowmeter with display

- Bronkhorst digital flow meter

- Ultrasonic flowmeter

- Bronkhorst IP65 flow meter

- Bronkhorst explosion-proof flow meter

- Aluminum flowmeter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.