Thermal evaporator CEM-Systemvacuumprocessfor liquids

Add to favorites

Compare this product

Characteristics

- Type

- thermal, vacuum

- Laboratory/process

- process

- Applications

- for liquids, gas

Description

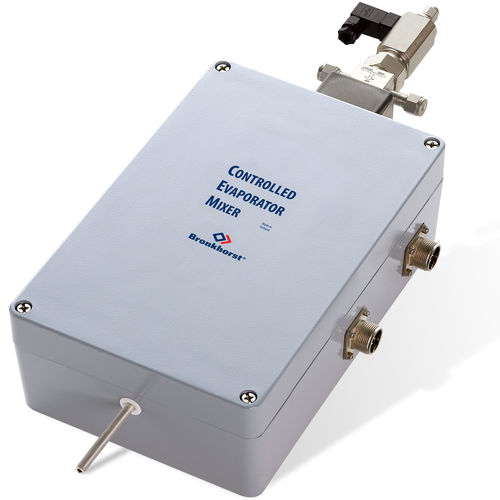

Our unique and patented 'CEM' technology, which stands for Controlled Evaporation Mixing, is developed for accurate vapour flow control. Traditional bubbler systems are often not capable of handling sufficient quantities of liquid with a low vapour pressure, or perform in an imperfect way. Moreover, they cannot instantaneously provide vapour of a mixture of liquids with different vapour pressures. These issues are overcome with our vapour delivery solutions.

The CEM-System (Controlled Evaporation and Mixing) is an innovative Liquid Delivery System (LDS) that can be applied for atmospheric or vacuum processes. The vapor generation system consists of a (thermal or Coriolis) liquid flow controller, an MFC for carrier gas and a temperature controlled mixing and evaporation device. The system is suitable for mixing liquid flows of 1-1200 g/h resulting in saturated vapor flows of 50 mln/min up to 100 ln/min. This vaporizer system can replace bubblers. New opportunities created with the CEM-system: mixtures can be evaporated and even solids, dissolved in solvents can be vaporised successfully.

Features

•accurately controlled gas/liquid mixture

•fast response

•high reproduceability

•very stable vapour flow

•flexible selection of gas/liquid ratio

•lower working temperature than conventional systems

•optional control by PC/PLC (RS232/fieldbus)

VIDEO

Catalogs

E-8000

8 Pages

Plastics & Rubberr Market

4 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Hyvolution 2025

28-30 Jan 2025 paris (France) Stand 4T23

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.