Thermal mass flow meter GF 125 differential pressuremassfor gas

Add to favorites

Compare this product

Characteristics

- Technology

- thermal mass, differential pressure

- Type

- mass

- Fluid

- for gas

- Installation

- in-line

- Communication

- RS485

- Supply voltage

- 5 VDC

- Protection level

- corrosion-resistant

- Other characteristics

- combined

- Process temperature

Max.: 50 °C

(122 °F)Min.: 0 °C

(32 °F)- Process pressure

Max.: 10.34 bar

Min.: 0 bar

(0 psi)- Precision

0.35 %, 1 %

- Repeatibility

0.15 %

Description

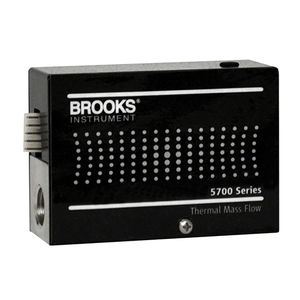

Fast responding, repeatable delivery of process gases with high and ultra-high levels of purity—that’s the performance the GF100 series of metal sealed mass flow controllers and meters provides. Designed for semiconductor, MOCVD and other gas flow control applications, the GF100 series exceeds the semiconductor industry standard for reliability, ensuring repeatable, highly stable performance over time. Standard MultiFloTM technology enables one MFC to support thousands of gas types and range combinations without removing it from the gas line or compromising on accuracy.

The result: increased process flexibility and efficiency combined with the industry’s highest levels of process gas purity to help maximize yields and productivity.

Features

Long-term zero stability of <±0.5% full scale per year

Settling times: 300 ms - <700 ms or 700 ms - <1 second

Full-scale flow rates up to 300 slpm

All-metal seal flow path: option for 4µ or 10µ inch Ra surface finish

Corrosion-resistant Hastelloy® T-Rise sensor improves measurement reproducibility at elevated temperatures

MultiFloTM gas and range programmability—one device, thousands of gas types and range combinations without removing the MFC from the gas line or compromising accuracy

Local display

Optional SDS gas delivery

DeviceNetTM, RS-485 L-Protocol and analog interfaces

Benefits

High-performance components marathon tested to seven times semiconductor industry standards for reliability

All metal, corrosion resistant flow path with reduced surface area and unswept volumes ensures faster dry-down during purge steps

With MultiFloTM, new process gases and/or ranges can be set in under 60 seconds – no more removing and calibrating

VIDEO

Catalogs

GF125 Series

12 Pages

GF100 Series

12 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Brooks instruments flow meter

- Volume flowmeter

- Liquid flowmeter

- Pressure transmitter

- Pressure gauge

- Analog pressure transmitter

- Brooks instruments gas flow meter

- Brooks instruments stainless steel flow meter

- Analog pressure indicator

- Waterproof flowmeter

- Pressure switch

- Industrial flowmeter

- Stainless steel pressure transmitter

- Membrane pressure transmitter

- In-line flowmeter

- Precision flowmeter

- Stainless steel pressure indicator

- Compact flowmeter

- Dial pressure indicator

- Water flowmeter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.