Monitoring software Compass 6000 CMSplanninginterfacecondition monitoring

Add to favorites

Compare this product

Characteristics

- Function

- interface, monitoring, planning, condition monitoring

- Applications

- process, rotating machinery

Description

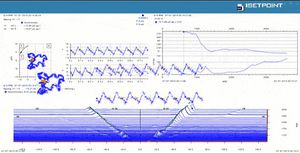

MODULAR CONDITION MONITORING AND DIAGNOSTICS

Compass 6000 helps detect faults early for improved maintenance planning and automatically trends the health of rotating machinery. To do that, the system acquires vibration and process data via Brüel & Kjær Vibro’s own rack-based VIBROCONTROL 6000® . Alternatively, it can connect to any other supplier’s machine protection system using the Condition Monitoring Interface VI-6080. Compass’s monitoring information can be easily exported to a number of different systems.

Compass 6000 provides integrated, plant-wide monitoring capability to a number of industries and a wide range of machines. The system is fully scalable. This means, it is in use with single machines up to a series of interconnected production plants with hundreds of machines. Compass 6000™ has been designed to optimize performance, uptime, and reliability of our customers’ machines.

An extensive service and after-sales portfolio including long-term service contracts ensures the system is always up to date.

Catalogs

VIBROCONTROL 6000

8 Pages

Related Searches

- Analysis software solution

- Process software solution

- Online software

- Monitoring software solution

- Measurement software

- Interface software

- Visualization software solution

- Machine software

- Planning software

- Data acquisition software

- Software suite

- Chemical software

- Monitoring software suite

- Pump software

- Rotating machinery software

- Interface software suite

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.