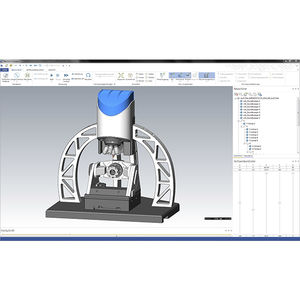

Shape measuring instrument EdgeMasterX3Dopticalcutting tool

Add to favorites

Compare this product

Characteristics

- Measured value

- shape

- Technology

- 3D, optical

- Applications

- cutting tool, cutting edge

- Configuration

- benchtop

- Other characteristics

- automatic

Description

The system: Automatic multi edge measurement

The EdgeMasterX is a fully automatic cutting edge measurement device for production integrated quality assurance of inserts, drills, millers and other tap tools. In particular, the automatic measurement system is designed to achieve automatic multi edge measurement of tools. In only one measurement cycle a series of user defined measurements are achieved. Results are traceable, repeatable and in a high vertical resolution. Deviations to GD&T data or reference geometry are listed automatically.

The benefits: Automatic measurement of multiple edges

Users can measure defined edge parameters on various tool positions to verify, for example, cutting edge preparation processes. In addition, form and roughness of a specific position can be analyzed and compared across multiple tools within a batch. When utilized in combination with a motorized rotation unit, users benefit from the measurement of multiple tool edges, even chamfered edges, in one single measurement run. The user interface design is simplistic and user-friendly having a single button solution allowing for measurements to occur without any further user interactions. Upon completion of the scan, deviations from a CAD dataset are easily visible as a traffic light system is used to indicate differences and non-conformities.

The applications: High resolution cutting edge measurement systems in production

The EdgeMasterX originates from the Alicona product line for automatic tool measurement and represents and enhancement of the original EdgeMaster.

Catalogs

EdgeMasterX

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Measuring device

- Measuring machine

- Portable measuring device

- Optical measuring machine

- Industrial gauge

- Automatic measuring machine

- High-precision measuring machine

- Measuring system for industrial applications

- Parts measuring machine

- Benchtop measuring device

- Automatic measuring device

- Control measuring machine

- Laboratory measuring device

- CMM

- Geometry measuring device

- Surface measuring machine

- Dimensional measuring machine

- 3D measuring machine

- Optical measuring device

- Industrial profiler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.