Roughness measurement system InfiniteFocusG6coordinatedimensionaloptical

Add to favorites

Compare this product

Characteristics

- Measured physical value

- coordinate, roughness, dimensional

- Technology

- optical, 3D

- Operating mode

- fully-automatic

- Measured material

- for gears

- Applications

- for industrial applications, for the automotive industry

- Configuration

- vertical

- Other characteristics

- high-precision, smart, high-resolution, rugged

Description

Dimensional Metrology & Surface Roughness Measurement in one system

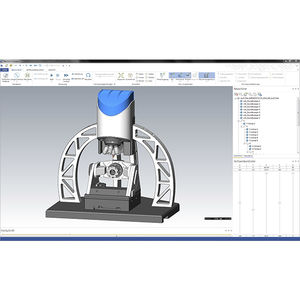

InfiniteFocusG6

InfiniteFocusG6 is an accurate, fast and universal optical 3D measuring instrument for tolerances in the µm and sub-µm range. Components are measured area-based and with high resolution, independent of size, material, geometry, weight and surface finish. A number of proven as well as new features combine the functionalities of a roughness measuring system (Ra, Rq, Rz/Sa, Sq, Sz) with the characteristics of a coordinate measuring machine.

The InfiniteFocusG6 stands for:

- Unrivaled measurement performance

- Groundbreaking user experience

- Future-proof technologies

- Smart Design

System features:

- MetMaX user software: Users specify measurements already on the CAD model of a component. A digital twin combined with a virtual measurement simulation enables safe operation of the measuring instrument.

- 5-axis-metrology: The expansion from 3 to 5 axes allows measurements of geometries that are otherwise difficult or impossible to access. High-precision tilting and rotating axes enable the measurement of GD&T and roughness parameters on the entire measured object.

- SmartFlash & Real3D: The integrated SmartFlash technology ensures high-resolution measurements of smooth, reflective and highly polished surfaces. Real3D turns measurements of complex micro geometries into a complete 360° data set.

- Vertical Focus Probing: The latest technology enables the optical lateral probing of components. Users measure holes and vertical flanks (>90°).

- Focus-Variation: The robust technology and the vibration-insensitive design ensure high-resolution and repeatable results, even in production.

Catalogs

No catalogs are available for this product.

See all of Bruker Alicona‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Measuring device

- Measuring machine

- Portable measuring device

- Optical measuring machine

- Industrial gauge

- Automatic measuring machine

- High-precision measuring machine

- Measuring system for industrial applications

- Benchtop measuring device

- Parts measuring machine

- Automatic measuring device

- Control measuring machine

- Laboratory measuring device

- CMM

- Geometry measuring device

- Surface measuring machine

- Dimensional measuring machine

- Industrial profiler

- Optical measuring device

- 3D measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.