- Products

- Catalogs

- News & Trends

- Exhibitions

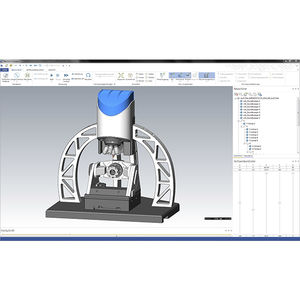

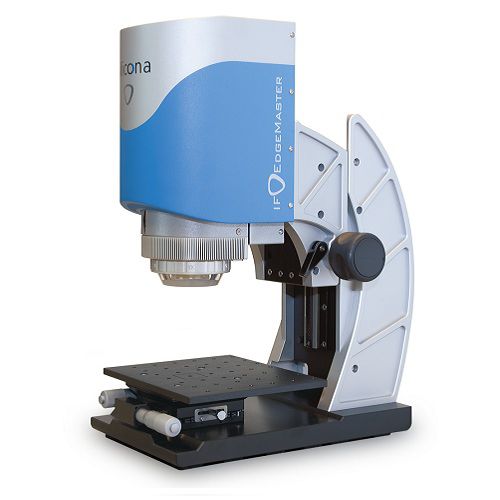

Shape measuring instrument EdgeMasterroughnessoptical3D

Add to favorites

Compare this product

Characteristics

- Measured value

- shape, roughness

- Technology

- optical, 3D

- Applications

- cutting edge, cutting tool

- Configuration

- benchtop

- Other characteristics

- automatic

Description

How to measure cutting edges also in production

The EdgeMaster is an optical 3D measurement device for automatic cutting edge measurement. Edges are measured regardless of type, size, material or surface finish of the tool. Users measure radii > 2µm as well as rake, wedge and clearance angle of cutting edges. Different types, including both waterfall and trumpet, are precisely measured. The robust technology of Focus-Variation delivers stable and traceable measurements also in

a production near environment.

The EdgeMaster delivers fully automatic measurements and stable results even with external vibration and external light. The system provides user friendly operation with high measurement speed. High vertical resolution enables chipping measurement in addition to traceable roughness

measurements at the rake face of edges. An intelligent illumination technology enables optimized illumination of surfaces with short exposure times, leading to fast measurements.

Users benefit from high resolution measurements during the whole manufacturing process. The EdgeMaster is used to measure the green part of a tool as well as the highly polished component in its final stage. Typically, the measurement system is used to measure

inserts, drills, millers etc. Advanced visualization including registered color information allows transparent and provable quality assurance.

Catalogs

Related Searches

- Measuring device

- Measuring machine

- Portable measuring device

- Optical measuring machine

- Automatic measuring machine

- Industrial gauge

- High-precision measuring machine

- Measuring system for industrial applications

- Parts measuring machine

- Automatic measuring device

- Benchtop measuring device

- Control measuring machine

- CMM

- Laboratory measuring device

- Geometry measuring device

- Surface measuring machine

- Dimensional measuring machine

- 3D measuring machine

- Industrial profiler

- Measuring system for the automotive industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.