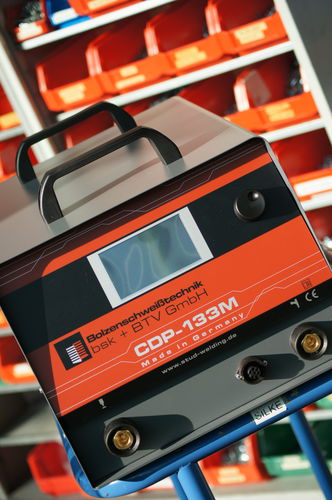

Arc welder CDP-133Melectrodesingle-phaseAC

Add to favorites

Compare this product

Characteristics

- Technique

- arc

- Consumables

- electrode

- Power supply

- single-phase

- Output current

- DC, AC

- Other characteristics

- inverter, high-performance

- Intensity

16 A

- Output frequency

Max.: 60 Hz

Min.: 50 Hz

Description

Digital distance measurement (lift, immersion, stud overhang, speed) and digital process monitoring (also of the welding current and the energy content) and many other library functions for permanently stored or variably saved welding parameters, including optional multi-point operation.

Electronically clocked inverter charging parts enable very short charging cycles with a high welding rate: this means that very high cycle rates are possible;

Monitoring and quick regulation of all parameters and functions in the welding circuit by high-performance microprocessor;

Capacitor capacity monitoring;

Digital position measuring system makes this possible even without optional process monitoring and recording

easy adjustment of bolt overhang and lift;

If the preset minimum values for bolt protrusion, lift and melt-off are not reached

(immersion) automatic information by color coding of the respective parameter even without

Activation of the full process monitoring;

Soft start function for gentle charging of the capacitors after a long standstill;

STOP function for all error messages (device-internal or process-related), ie automatic

interruption of welding operation;

State-of-the-art HMI: Simple dialog operator guidance through menu structure and one-button operation as well as display of all parameters relevant to the operator on a large four-inch graphic display;

Library function: Stored standard welding programs and additional variable, user-defined welding programs can be saved;

Numerous special functions for complex welding tasks;

Low weight and compact design

Catalogs

No catalogs are available for this product.

See all of bsk + BTV GmbH‘s catalogsRelated Searches

- Welding system

- Automatic welding system

- Welder

- Arc welder

- Manual gun

- Mobile welder

- Metal welding system

- Laser welding system

- Arc welding system

- Inverter welder

- DC welder

- Single-phase welder

- Standalone welding system

- PLC-controlled welding system

- Electrode welder

- 220V single phase welding system

- Welding gun

- AC welder

- Automatic welding head

- Stud welding gun

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.