- Building - Construction

- Construction and Mining Equipment

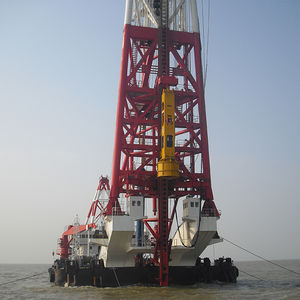

- Hydraulic pile-driving hammer

- BSP International Foundations Limited

Hydraulic pile-driving hammer DX series

Add to favorites

Compare this product

Characteristics

- Specifications

- hydraulic

Description

The DX range of hydraulic piling hammers are designed for small bearing piles of steel, timber, concrete and many sheet piles. The DX hammer is available with back guides for operating from a piling mast or a slider for operating from an excavator.

DX Hammer Main Image

The DX hammer can be mounted on road, rail or tracked excavators with an operating weight of around 32t or greater. Applications include railway equipment installation and maintenance. Specifically developed to drive steel piles to support electrification stanchions, gantries and other railway projects requiring foundation piling. When mounted to the excavator’s bucket linkage, the hammer can be quickly erected from a horizontal transport position to a vertical position. Side tilt adjustment of five degrees left and right allows it to cope with the cant of the rail lines. During piling the hammer is automatically guided or crowded in the vertical plane.

Read More

Three models are available, the DX20, DX25 and the larger DX30, which offer drop-weights of 1.5t, 2.0t and 2.5t. Maximum impact energy is 20kNm, 25kNm and 30kNm respectively while blow rate at rated energy for or models is approximately 60 blows per minute.

DX hammers can also be used to drive sheet piles, small bearing piles, tubular steel piles, timber or concrete piles with ultimate load bearing up to 1800kN. They can be operated directly from a suitable hydraulic excavator. A feature of the new hammers is an innovative BSP double-acting cylinder, whereby the ram is accelerated on its downward path to achieve higher impact energy.

Catalogs

No catalogs are available for this product.

See all of BSP International Foundations Limited‘s catalogsOther BSP International Foundations Limited products

Hydraulic Piling Hammers

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.