- Materials - Tools - Components

- Hand Tool, Power Tool

- Punch

- BTM Europe Blechverb. GmbH

Punch Tog-L-Loc®

Add to favorites

Compare this product

Description

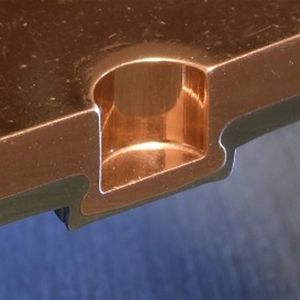

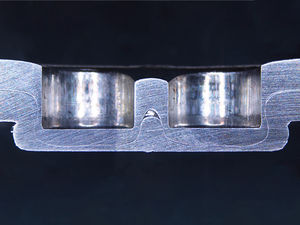

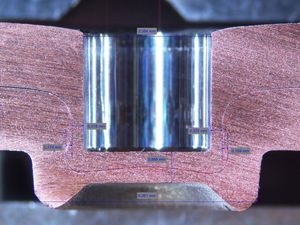

The round Tog-L-Loc® clinch joint is the best-known clinching system on the market. The round joints are produced by cold forming the layers. They connect sheet metals and/or profiles of different material types and thicknesses. Initially with two movable blades, then later as the first manufacturer worldwide with a 3-bladed die design, BTM was the pioneer of modern clinching technology

The Tog-L-Loc® round joint from BTM is characterised by its non-cutting joining process. The joining layers are locked together in a circular manner, i.e. over 360°. The round clinch joint is equally leak proof in all planes in all directions and both metal sheet layers – punch and die sides – remain leak proof.

In a second step, Tog-L-Loc® clinch joints can also be pressed flat to create a two flat metal sheet/partner surface.

Catalogs

Other BTM Europe Blechverb. GmbH products

Clinching Systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.