- Materials - Tools - Components

- Hand Tool, Power Tool

- Punching die

- BTM Europe Blechverb. GmbH

Punching die Oval-Loc®

Add to favorites

Compare this product

Description

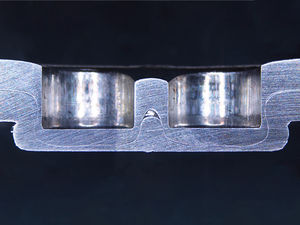

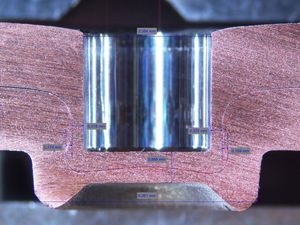

Oval-Loc® was created from the vision of combining all of the advantages of our popular Tog-L-Loc® round clinch joint with the rotation resistance of our Lance-N-Loc® sheet metal joining system. The Oval-Loc® process features the leak-proof and long tool life characteristics of a traditional Tog-L-Loc® joint, but also provides improved strength. It is characterised by its compact, space-saving design and offers an excellent alternative to the usual twin and multi-joint solutions.

As part of the GEO-Clinch® family, the Oval-Loc® is particularly suitable for the automotive industry, where several components are pre-fixed in GEO stations. With just one BTM Oval-Loc®Clinch, two components can be joined tightly, corrosion-proof, at the same time as possessing a high torsional resistance.

A typical Oval-Loc® joint may be created in a as little as one second. The process is very similar to Tog-L-Loc®:

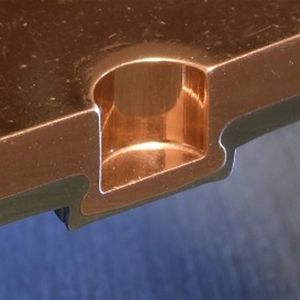

Clamps: The stripper clamps the materials to be joined.

Draws: The punch draws the material into the die.

Locks: As the material flows into the die, the sides of the die expand, allowing the material to flow into an interlock.

Catalogs

Oval-loc Clinch Tooling

16 Pages

Overview Hand-Held Clinch Units

36 Pages

Other BTM Europe Blechverb. GmbH products

Clinching Systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.