- Power Transmission - Mechanical components

- Mechanical Transmission

- Cross universal joint

- BTM Europe Blechverb. GmbH

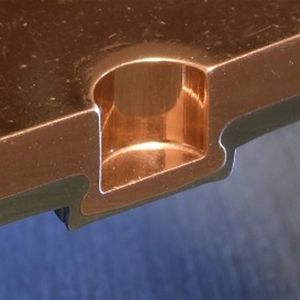

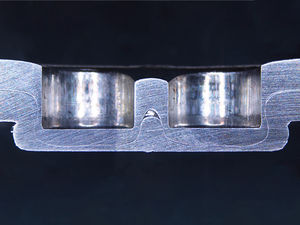

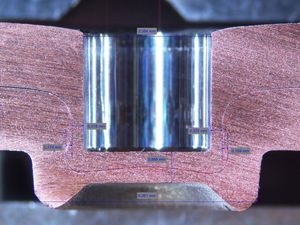

Hollow universal joint Oval-Loc®cross

Add to favorites

Compare this product

Characteristics

- Configuration

- hollow, cross

Description

Oval-Loc® was created from the vision of combining all of the advantages of our popular Tog-L-Loc® round clinch joint with the rotation resistance of our Lance-N-Loc® sheet metal joining system.

Now you can assemble your sheet metal parts with even less cost using our innovative Oval-Loc® clinch tools which deliver the following advantages:

Parts with limited overlap area and requiring a non-rotating connection can be joined using a single Oval-Loc® punch and die

Oval-Loc® offers tool life similar to Tog-L-Loc®, is also leakproof, and keeps coatings intact.

The non-round shape creates non- rotating rigidity and high strength with only one joint.

This makes Oval-Loc® ideal for setting the orientation geometry or “GeoClinching” assembled parts. Now parts can be inexpensively “tacked” together to significantly reduce the cost of tooling for spot welding sheet metal assemblies by reducing the amount of clamps and gaging required during ongoing welding steps.

Catalogs

Oval-loc Clinch Tooling

16 Pages

Overview Hand-Held Clinch Units

36 Pages

Other BTM Europe Blechverb. GmbH products

Clinching Systems

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.