- Products

- Catalogs

- News & Trends

- Exhibitions

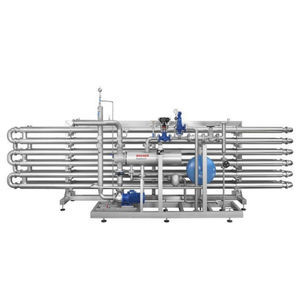

Thermal evaporator falling filmprocessfor dairy products

Add to favorites

Compare this product

Characteristics

- Type

- thermal, falling film

- Laboratory/process

- process

- Applications

- for dairy products

Description

Evaporator systems for various applications in the dairy industry

Evaporators, also known as concentrators, have been used for more than a century (since 1913). As well as multistage steam-heated evaporators, Bucher Merk also supplies plants with thermal or mechanical vapour recompression. PLC-based controls allow the simple and user-friendly supervision.

Falling film evaporators with mechanical vapour recompression (MVR)

Evaporators with Mechanical Vapour Recompression (MVR) are operated with a high-pressure blower where the recompressed steam is used for the heating of the product. An MVR-evaporator can run on relatively low evaporation temperatures. Thanks to the low thermal load, concentrated products of superior quality can be produced. MVR-evaporators have considerably lower evaporation costs when compared to other designs. To evaluate this, it’s vital to consider the costs for steam, electricity and cooling water. Our specialists are eager to advise you on the most economical solution for your task.

Thanks to our broad experience in designing evaporators, Bucher is your ideal partner for solutions for the concentration of:

Whole-milk and skimmed milk

Whey

Condensed Milk

Technical data for milk evaporators

Type: Falling film evaporator

Evaporation capacity: up to 50 t/h per unit

Vapour recompression: mechanical or thermal

Catalogs

No catalogs are available for this product.

See all of Bucher Unipektin AG‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.