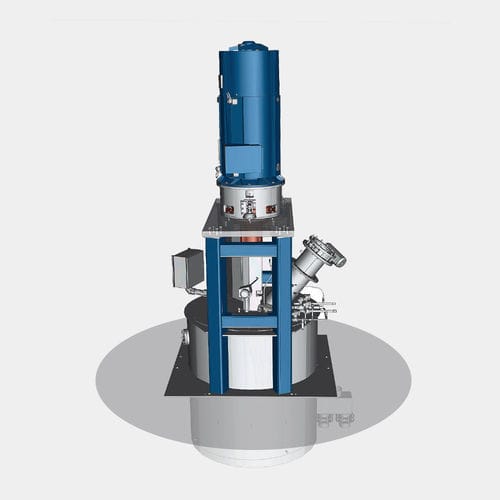

Centrifuge for the sugar industry BW seriesfloor-standingverticalbatch

Add to favorites

Compare this product

Characteristics

- Applications

- for the sugar industry

- Configuration

- floor-standing

- Orientation

- vertical

- Other characteristics

- batch

Description

Buckau-Wolf discontinuous centrifugals are used in the production of white sugar and raw sugar massecuite in the sugar industry, dextrose, mannite, xylite, isomalt and fructose massecuite, sugar substitutes,

Buckau-Wolf discontinuous centrifugals have a very lean drum design.

Advantages

• Maximum separation performance through very high spinning factors of up to 1,500 g

• Colour removal up to 98 %. The residual moisture in white sugar massecuite can be reduced to as little as 0.5 %.

Buckau-Wolf discontinuous centrifugals work with minimal water resources to avoid sugar loss and an extremely low power consumption of less than 1 kWh/batch in the production of white sugar.

Buckau-Wolf discontinuous centrifugals use a controller developed by Buckau-Wolf which fulfils extreme requirements of our customers.

Advantages

• Precise, exactly reproducible massecuite layer thicknesses in every cycle due to continuous monitoring of filling quantities

• The BWS controller enables optimum use of drum capacity in each batch

• Integration of the controller into higher-level process control system

• System-wide communication network enables intelligent locking of connected centrifugals

Buckau-Wolf discontinuous centrifugals are easy to use and come with comprehensive diagnostic features.

Advantages

• Language-independent, self-explanatory GUI on the operating panel

• Intuitive operation due to high degree of automation

• Quick, comprehensive diagnostic features to localise and analyse errors and avoid downtime in the event of malfunction

• Extra functions for service support

Buckau-Wolf discontinuous centrifugals offer extremely high operational safety.

Catalogs

No catalogs are available for this product.

See all of Buckau-Wolf GmbH‘s catalogsRelated Searches

- Vertical centrifuge

- Homogenizer

- Dynamic homogenizer

- Homogenizer for the food industry

- Floor-standing centrifuge

- Process centrifuge

- Liquid homogenizer

- Homogenizer for the chemical industry

- Continuous homogenizer

- Continuous centrifuge

- Centrifuge for the food industry

- Crystallizer

- Batch centrifuge

- High-shear homogenizer

- Horizontal homogenizer

- Food crystallizer

- Centrifuge for the sugar industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.