- Machine-tools

- Machining Center

- Rotary transfer machine

- BUFFOLI TRANSFER

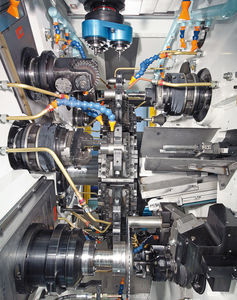

Rotary transfer machine MICRO-FLEXCNCwith rotary tablevertical-axis

Add to favorites

Compare this product

Characteristics

- Type

- rotary

- Control type

- CNC

- Other characteristics

- with rotary table, vertical-axis

Description

High speed flexible transfer machine for the production of small and complex parts. The machine can be equipped with an integrated bar loader and cut off unit without the need for an intermediate loading stage (high efficiency).

The machine is equipped with a suspended vertical axis rotary table and CNC electro-spindles (up to 40.000 rpm) on CNC cross slides.

The rotary table carries the CNC horizontal rotary axis satellites with the clamping fixtures.

The rotating satellites have an independent built-in indexing drive avoiding external engagement systems and consequent complexity and longer idle time.

Angular positioning of the clamping fixtures can be CNC programmed at each station thus offering the maximum flexibility to adopt different machining strategies for a wide range of 5-sided components.

Clamping fixtures can be designed to allow secondary positioning of the part to complete machining of the 6th side.

The machine is designed to utilize emulsion, integral oil or to operate in dry machining, and, the suspended rotary table and horizontal rotating fixtures makes for an ideal machining and evacuation of long swarf materials.

VIDEO

Catalogs

No catalogs are available for this product.

See all of BUFFOLI TRANSFER‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- Horizontal CNC machining center

- CNC machining center with pallet changer

- 24 tools CNC machining center

- Turning-milling machine

- CNC machining center with rotary table

- CNC turning-milling center

- 4-axis CNC machining center

- CNC transfer machine

- Rotary transfer machine

- Multi-spindle transfer machine

- Vertical turning-milling center

- Machining transfer machine

- Vertical-axis transfer machine

- Horizontal-axis transfer machine

- High-productivity transfer machine

- Turning transfer machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.