- Production Machines

- Forming Machine

- Manual press

- BUGATOOL MACHINES SL

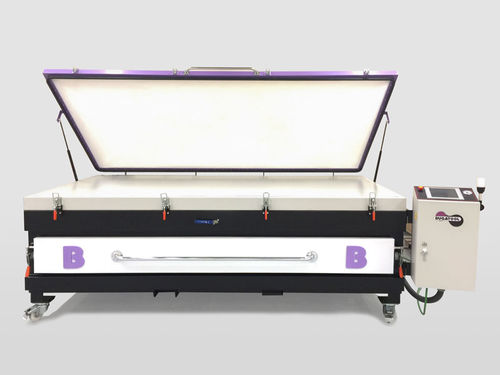

Manual press Buga Duo 2612electricbendingfor molding

Add to favorites

Compare this product

Characteristics

- Operation

- manual, electric

- Function

- bending, for molding, heat transfer

- Structure

- compact

- Control

- automatic, PLC-controlled, pressure vacuum-piloted

- Other characteristics

- digital, with heating plates, high-pressure, vacuum, membrane

- Applications

- for carbon fiber-reinforced plastic parts, for the aeronautical industry, for the wood industry, for the furniture industry, for thermoforming lines, for plastics, for snowboards, panel, for Corian®

- Table length

Min.: 1,100 mm

(43 in)Max.: 1,300 mm

(51 in)- Max. pressure

Min.: 0 bar

(0 psi)Max.: 1 bar

(15 psi)- Overall length

3,300 mm

(130 in)- Overall width

1,700 mm

(67 in)- Overall height

1,050 mm

(41 in)

Description

The BUGA Duo 2612 is the smartest duo oven and membrane press in its class.

The oven and the vacuum press are mounted on the same chassis to optimize the space in your workshop and optimize its use.

The machine is equipped with a PLC (Programmable Logic Controller) assisted by a 13-inch touch screen allowing the application of 20 programs. Two “k” probes tell you the core temperature of the material during heating and cooling. This way you control at any time the heating of your resin plate regardless of its size.

This patented technology gives the BUGA Duo an unprecedented level of reliability.

Because heating the solid surfaces should not obey only the variable time.

The BUGA Duo 2612 is suitable for industrial thermoforming of Solid surface, PMMA and other thermoformable polymers.

The manufacturing rate is about 25 minutes per 12 mm thick panel.

2 mm thick silicone membrane press, supports up to 230ºC

• The silicone membrane has 700% elasticity a shore A 45/50 and a specific weight of 1.2 gr/cm3

• Becker brand 40m3/h maintenance-free vacuum pump

• Maximum pressure: 9 t/m2

• Automatic or manual work mode

• Multi perforated and epoxy lacquered metal vacuum table

• Hot air furnace ventilated by 3 circuit turbines specially designed for its homogeneity and patented.

Maximum temperature: 190ºC

• Triple temperature control with 2 “k” probes and one PT100 probe

• Oven insulated with 50 mm rock wool

• 13” touch screen with 20 programmable menus

• Buzzer sound and light to indicate the end of the cycle

VIDEO

Catalogs

BUGA DUO 2612

2 Pages

Related Searches

- Industrial press

- Forming press

- Automatic press

- Electric press

- Manually-controlled press

- PLC-controlled press

- Bending press

- Hot press

- Compact press

- Plastic press

- Molding press

- Digital press

- High-pressure press

- Composite material press

- Heat transfer press

- Panel press

- Wood press

- Press with heating plates

- Vacuum press

- Press for the aeronautical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.