- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Food industry sieve DMHXcentrifugalfor bulk materials

Add to favorites

Compare this product

Characteristics

- Applications

- for the food industry

- Type

- centrifugal

- Material

- for bulk materials

Description

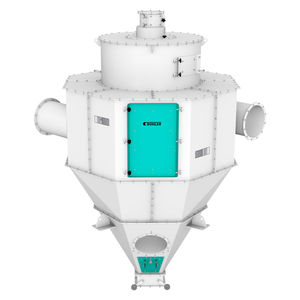

Centrifugal Sieve DMHX

Bühler is a leading manufacturer of food processing and animal feed processing equipment. The Bühler centrifugal sieve DMHX is specifically designed as animal feed processing equipment. Its main application is the check screening of finished products. The centrifugal sieve separates and sieves foreign objects, husks and lumps from floury, mealy or granular materials in the feed manufacturing, oil milling, food processing and similar industries.

Designed to deliver high quality, uniform end products.

The centrifugal sieve DMHX pushes material entering the unit against the screen jacket while simultaneously conveying it slowly toward the outlet, thereby disintegrating even smaller lumps. This results in exceptionally clean, high quality products.

Guarantees uniform particle sizes and end products free of contaminants when applied as a control sieve.

Excellent operating efficiency through continuous self-cleaning.

Brushes attached to the rotor clean the screen, ensuring a high separating efficiency. Active sieving area up to 278 dm², depending on machine model.

Top sanitation through easy cleaning.

The centrifugal sieves design enables high sanitation standards thanks to easy access for cleaning and maintenance.

Catalogs

Centrifugal_Sieve

2 Pages

Related Searches

- Bühler mill

- Bühler screener

- Bühler bulk material screener

- Bühler horizontal mill

- Vertical grinding mill

- Bühler food mill

- Vibrating sieving machine

- Bühler impact mill

- Bühler roller mill

- Building materials grinding mill

- Sieving machine for the food industry

- Bühler hammer mill

- Bühler mill for the food industry

- Sifter

- Compact screening machine

- Process centrifuge

- Powder sieving machine

- Stainless steel sieving machine

- Ball grinding mill

- Automatic grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.