Magnetic belt conveyor MS serieslow-profile belthorizontalinclined

Add to favorites

Compare this product

Characteristics

- Technology

- magnetic belt, low-profile belt

- Form

- horizontal, inclined, straight, Z type

- Function

- transport

- Construction

- enclosed, mobile

- Drive mechanism

- electric drive

- Transported product

- chip, for small parts

- Applications

- for heavy-duty applications

- Effective width

Max.: 30 in

Min.: 4 in

Description

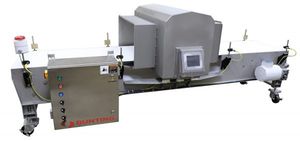

Bunting’s MagSlide® magnetic chip conveyors are built to handle your toughest conveying jobs. Designed for the most punishing jobs, the unique magnetic conveying system present in the MagSlide conveyor provides trouble-free, virtually maintenance-free operation. The MagSlide® utilizes powerful magnetic conveying to hold and transport even the dirtiest, most abrasive materials. The rugged construction of the MagSlide conveyor provides dependable performance that is suitable for even the most demanding jobs.

MagSlide conveyors are engineered to provide you outstanding performance and value. When handling materials such as dirty and oily metal chips, parts, jagged or abrasive scrap, and other punishing materials, conventional belted or steel hinged conveyors risk being damaged. Bunting’s MagSlide conveyors eliminate the problems that conventional conveyors struggle with. The MagSlide® has no external belts, so there’s no risk of belts jamming, tearing, or wearing out over time when conveying sharp, abrasive parts and scrap material. The MagSlide® has no external moving parts, eliminating the risk of such parts failing and compromising productivity and worker safety. Maintenance on the MagSlide® is minimal, and aside from the electric motor, all moving parts are totally enclosed.

The MagSlide® is available in several different configurations. Options include horizontal, incline, and angled models with fixed and mobile bases. Additionally, options including hoppers, tanks, and impact plates are also available.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Bunting-Newton‘s catalogsRelated Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Electric drive conveyor

- Inclined conveyor

- Mobile conveyor

- Heavy load rail conveyor

- Part conveyor

- Straight conveyor

- Chip conveyor

- Conveyor for heavy-duty applications

- Z type conveyor

- Enclosed conveyor

- Magnetic belt rail conveyor

- Small part conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.