Magnetic pulley for belt conveyorscustomadjustable

Add to favorites

Compare this product

Characteristics

- Type

- magnetic

- Applications

- for belt conveyors

- Other characteristics

- custom, adjustable, variable

Description

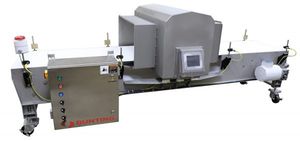

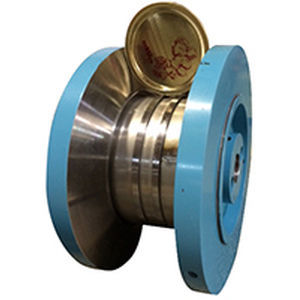

Bunting manufactures a diverse selection of adjustable Magnetic Upstacking Pulleys, available in many different sizes. Our custom manufactured Magnetic Upstacking Pulleys can be used on can lids, jar lids, oil filter tapping plates, and many other uniform lid and filter type ferrous metal items. Magnetic Upstacking Pulleys are typically 3 or 4 pole magnetic assemblies that are designed to snap in, stabilize, control, feed, and force lids into sleeves or feeding machines. Diameters of these pulleys are designed relative to the size of the lid.

Lids are usually fed into a Magnetic Upstacking Pulley by a high speed belted conveyor. The powerful magnetic field loops suck the lids into magnetic adjustable flanges, which secures the lids perpendicular to the pulley. The magnetic field is transmitted into the lids, which causes a similar pole repelling polarity. This keeps the lids fanned parallel to each other as they rotate around the pulley. As the Magnetic Upstacking Pulley rotates, the magnetic force on the lids works to force the lids into a track or sleeve.

They are usually independently driven with VFD variable speed drive motors to adjust the Magnetic Upstacking Pulley rotation speeds relative to the line speeds.

Transport Cans-Magnetic Assemblies-Magnetic Pulleys-Bunting-NewtonMagnetic Upstacking Pulleys can be used in a diverse range of industry, and efficiently handle many different types of can lids.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Bunting-Newton‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.