Separator with cylindrical magnet particlefor bulk materialsgranules

Add to favorites

Compare this product

Characteristics

- Technology

- with cylindrical magnet

- Separated substance

- particle, for bulk materials, granules, powder

- Application domain

- for the food industry, for in-line monitoring

Description

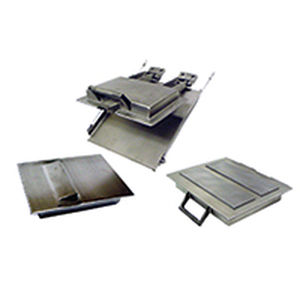

Center-Flow Magnets

Center-Flow In-Line Magnetic Separators are engineered to remove ferrous fines as well as larger pieces of tramp iron from dry particulates as they travel through dilute-phase pneumatic conveying lines.

To achieve optimum contact with the product flow, a conical magnet is suspended in the center-line of the housing. This tapered, exposed-pole cartridge has a stainless steel “nose cone” to direct the flow of materials around the magnet. The magnet’s tapered poles allow ferrous fines to collect out of the direct air stream, and the trailing end of the magnet is an active pole so that any tramp metal that might be swept down the cartridge will collect there.

• Installs easily in any position.

• Placement in vertical run makes optimum use of magnetic field.

• For dilute phase conveying up to 15 psi.

• Durable stainless steel nose cone directs material around magnet.

• Unclamp the cover and remove the magnet for cleaning.

• High-energy rare earth magnets are standard.

• Optional Clear View Inspection Port.

VIDEO

Catalogs

No catalogs are available for this product.

See all of BUNTING‘s catalogsRelated Searches

- Rail conveyor

- Transport conveyor

- Belt conveyor

- Horizontal conveyor

- Solid classifier

- Liquids separator

- Eddy current separator

- Inclined conveyor

- Handling conveyor

- Process classifier

- Gravity classifier

- Modular conveyor

- Bulk products conveyor

- Classifier for the recycling industry

- Particle classifier

- Classifier for the food industry

- Ferrous metal separator

- Transfer conveyor

- Mobile conveyor

- Vertical conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.