- Detection - Measurement

- Flow, Pressure and Level Measurements

- Vacuum leak tester

- Burhani Engineering Technology

- Products

- Catalogs

- News & Trends

- Exhibitions

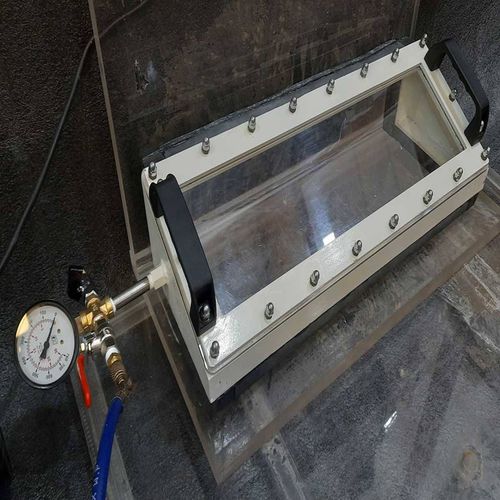

Vacuum leak tester BHFICV-6bubblecorner

Add to favorites

Compare this product

Characteristics

- Type

- vacuum

- Other characteristics

- bubble, corner

Description

The Benefits of Inside Corner Vacuum Box Bubble Leak Testing

24"L x 5 1/4"W x 5 1/4“ H

600 mm x 125 mm x 125 mm

1. High Sensitivity: This testing method is highly sensitive, capable of detecting even tiny leaks and imperfections that may compromise the integrity of a weld.

2. Non-Destructive: Inside Corner Vacuum Box Bubble Leak Testing is a non-destructive technique, meaning it does not alter or harm the weld in any way. This allows for repeated inspections without compromising the weld's integrity.

3. Accurate and Reliable: The formation of bubbles is a clear visual indicator of defects, making this method accurate and reliable in identifying issues within the weld.

4. Versatile Application: Inside Corner Vacuum Box Bubble Leak Testing is adaptable to various industries and applications, including pipelines, pressure vessels, storage tanks, and more.

5. Cost-Effective: This testing method is cost-effective, as it does not require expensive equipment or consumables, making it a practical choice for routine inspections.

6. Quick Results: Inspections using this technique provide immediate results, allowing for prompt decision-making and necessary repairs or modifications.

7. Enhanced Safety: Ensuring the integrity of welds is essential in industries where safety is paramount, such as petrochemical, nuclear, and aerospace sectors.

Catalogs

No catalogs are available for this product.

See all of Burhani Engineering Technology‘s catalogsOther Burhani Engineering Technology products

Vacuum Box For Leak Test NDT

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.