- Detection - Measurement

- Flow, Pressure and Level Measurements

- Vacuum leak tester

- Burhani Engineering Technology

- Products

- Catalogs

- News & Trends

- Exhibitions

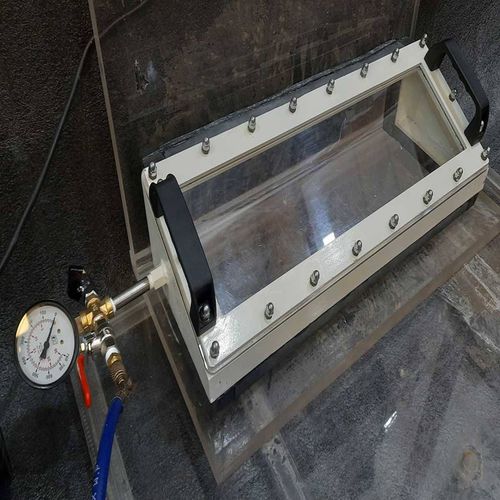

Vacuum leak tester BHFICV-10bubblecorner

Add to favorites

Compare this product

Characteristics

- Type

- vacuum

- Other characteristics

- bubble, corner

Description

Inside Corner Vacuum Box Bubble Leak Testing

Bubble leak testing of tank bottom plate welds and shell to bottom plate welds

40.00" L x 5 1/4"W x 5 1/4“

1000 mm x 200 mm x 150 mm

When it comes to ensuring the structural integrity of welds, especially those found in critical applications such as pipelines, pressure vessels, and industrial equipment, meticulous inspection methods are essential. Inside Corner Vacuum Box Bubble Leak Testing is a specialized non-destructive testing (NDT) technique that plays a pivotal role in detecting leaks and imperfections in welds, particularly in challenging inside corner joints. In this comprehensive guide, we will explore the world of Inside Corner Vacuum Box Bubble Leak Testing, uncovering its benefits, various applications, setup techniques, and essential tips to ensure accurate and reliable weld inspections.

The Burhani Engineering Technology vacuum box has been designed for the operators according to API 650/653 recommendations. Bubble leak or vacuum box testing is an integral part of tank inspections as required by the American Petroleum Institute (API) and other international standards associations to establish the condition of tank bottom plate welds and shell-to-bottom plate welds.

Catalogs

No catalogs are available for this product.

See all of Burhani Engineering Technology‘s catalogsOther Burhani Engineering Technology products

Vacuum Box For Leak Test NDT

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.