- Industrial machines and equipment

- Surface Treatment Equipment

- Vacuum chamber

- Burhani Engineering Technology

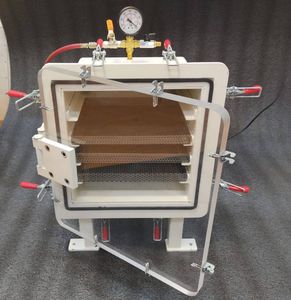

Degassing vacuum chamber BHF2545

Add to favorites

Compare this product

Characteristics

- Other characteristics

- degassing

Description

The vacuum chamber with pump India is loaded with epoxy resin or silicon rubber or Polyurethane rubber. The Vacuum Pump is started and diy vacuum degassing chamber process is started and it continues for 8 to 10 minutes based on type of resin and quantity.

Vacuum Degassing silicone is a process to remove gases and bubbles from compounds using vacuum chamber and vacuum pump. A diy vacuum degassing chamber is required to assure a bubble free mold when mixing silicone rubbers and mixing resin and slower setting harder resins.

Catalogs

No catalogs are available for this product.

See all of Burhani Engineering Technology‘s catalogsOther Burhani Engineering Technology products

Stainless Steel Cube Vacuum Chamber

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.