- Machine-tools

- Machine Tool Accessory

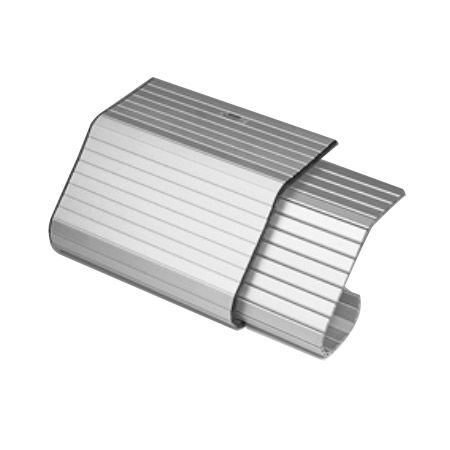

- Stainless steel apron cover

- Buww Coverings Inc.

- Products

- Catalogs

- News & Trends

- Exhibitions

Stainless steel apron cover for machines

Add to favorites

Compare this product

Characteristics

- Material

- stainless steel

- Other characteristics

- for machines

Description

WALK ON ROLL-UP COVERS are specially engineered to cover large machine tool way surfaces and open pits. Regardless of the size of the area being protected, these covers will easily endure constant use and support the weight of heavy chip loads and personnel. Additionally, by utilizing a flat stainless steel top surface, the contents under the cover are completely protected and contaminants such as cutting lubricants, hot chips, and dust cannot penetrate into the machine’s interior.

OPEN REEL TYPE ROLL-UP COVERS are extremely versatile and are build to protect machine areas where medium to light-duty protection is required.

Common features of open reel type roll-up covers:

.020” Neoprene/Nylon

.040” Neoprene/Nylon

.020” Viton/Fiberglass

.010” Teflon/Kevlar

CANISTER REEL TYPE ROLL-UP COVERS are essentially open reel covers mounted inside a protective canister. The canister serves to prevent contact between the covers moving take up mechanism and the external environment. This reduces the potential for accidents to personnel working near the take up mechanism, and also guards the take up mechanism and wound cover segments from damage that may result from shop accidents.

Common features of Canister Reel type covers:

.020” Neoprene/ Nylon

.040” Hypalon/Nylon

.020” Viton/Fiberglass

.010” Teflon/Kevlar

CANISTER STAINLESS STEEL ROLL-UP COVERS are used in the most harsh shop environments. Because of the covers underlying aluminum support structure, the cover is walk on capable and will easily bear the weight of heavy chip loads.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.