- Products

- Catalogs

- News & Trends

- Exhibitions

Dust collector filter bag polyesterfabricwelded

Add to favorites

Compare this product

Characteristics

- Applications

- for dust collectors

- Material

- polyester, fabric

- Type

- welded

Description

These mostly smaller filter systems (often with a filter area of only 5 - 200 m²) are preferable when discontinuous processes are involved, e.g. for the dedusting of conveyor systems, silos or workplaces.

Cleaning is carried out by means of a motorised (or manual) vibrating device that causes the filter bag to vibrate. The filter cake detaches from the filter bag and drops into a collecting container. Cleaning can only take place when filtration is off-line.

During cleaning, vibration subjects filter media to high mechanical stress. Since vibrating filters are usually only operated discontinuously and are not designed for long periods of continuous operation however, filter media with strong supporting fabric can still enjoy a service life of several years.

Your benefits at a glance

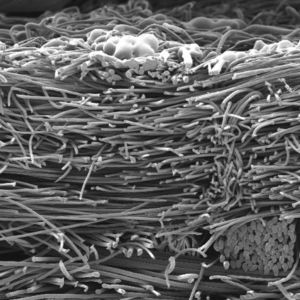

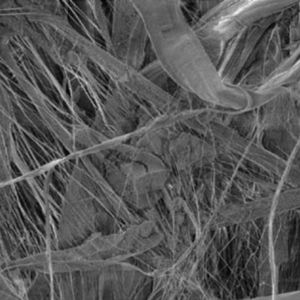

Polyester needle felt with a basis weight of 300 - 350 g/m²

Strong multi-filament supporting fabric ensures long service life

High air permeability

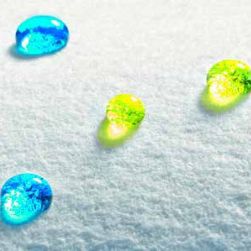

A smoothed filter media surface "glaze" supports filter cake release

Related Searches

- Filter cartridge

- Industrial filter cartridge

- General purpose filter cartridge

- Polymer filter cartridge

- Filter element

- Pleated filter cartridge

- Filter bag

- Air filter cartridge

- Gas filter element

- Air filter element

- Liquid filter element

- Polypropylene filter bag

- Gas filter cartridge

- Welded filter bag

- Dust filter cartridge

- Fiber filter medium

- Polyester filter bag

- Dust filter element

- Roll filter medium

- Air filter bag

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.