- Electricity - Electronics

- Cable, Connector, Enclosure

- Ethernet slip ring

- ByTune Electronics

- Products

- Catalogs

- News & Trends

- Exhibitions

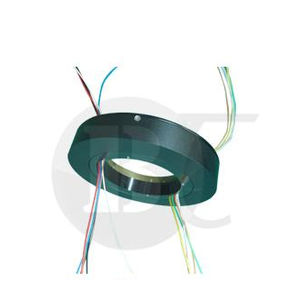

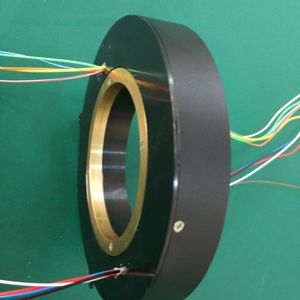

Electric slip ring BTH1256-1810EthernetsilverIP54

Add to favorites

Compare this product

Characteristics

- Type

- electric, Ethernet

- Material

- silver

- Other characteristics

- IP54, IP65

- Voltage

240 V, 380 V, 600 V

- Primary current

5 A, 10 A, 15 A, 20 A

- Rotational speed

1,000 rpm

(6,283 rad.min-1)

Description

Slip Rings For Bottle Filling And Capping System

Slip ring for bottle filling and capping system, BTH1256-1810 is one fitting choice for this kind of automation machine. ID12mm, OD56mm, 18 circuits, 10A for each circuit, anti-rotation tab installation designing. According to different types of bottle and capping system, ByTune slip rings still can add the Ethernet signal wire being compatible with the electric wire to realize the transmitting of the power and signal simultaneously. Short lead time, normal and safe dispatching, stable product quality, waiting for your consulting!

Brief Description

Slip ring for bottle filling and capping system, is a typical application of ByTune product in automation field. ByTune through hole series slip ring is the hot seller in our all product! Bottle filling and capping system slip ring, ByTune has a wide customization service for fitting diverse types machines. The dimension, the current magnitude, the number of circuit, the options of signal type, the rotation speed, installation designing and many others, ByTune dedicates all of us to fulfil your machines requirements! Trusting ByTune's 20+ designing and manufacturing experience in this field!

Parameters

Working speed

1000rpm

Operating temperature

-40℃~ +100℃

Contact material

Precious metal

IP Grade

IP 54, IP65 (or higher)

Circuit

6 ,12,18,24 (or more)

Current

5A,10A ,15A,20A or higher current

Voltage

240V,380V,600V optional

Dielectric strength

≥1000V@50Hz between each circuit

Insulation resistance

1000MΩ@500VDC

Electric noise

≤7mΩ

Lead wire size

22AWG, 17AWG,UL, color Teflon, silver or tin plated

Lead wire length

200mm optional

Related Searches

- Electrical rotary joint

- Wire slip ring

- Through-bore slip ring

- Electric electrical slip ring

- Slip ring for industrial applications

- Compact electrical slip ring

- IP54 electrical slip ring

- Capsule electrical slip ring

- Ethernet electrical slip ring

- Stainless steel electrical slip ring

- Aluminum alloy electrical slip ring

- Rotary table electrical slip ring

- Fiber brush electrical slip ring

- Flange electrical slip ring

- Custom electrical slip ring

- USB electrical slip ring

- IP65 electrical slip ring

- Multi-channel electrical slip ring

- Packaging slip ring

- Standard electrical rotary joint

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.