- Machine-tools

- Machining Center

- 3-axis CNC milling machine

- BZT Maschinenbau GmbH

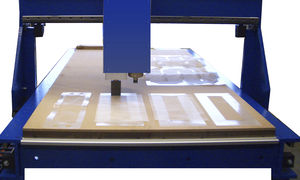

3-axis CNC milling machine universalbridgefor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- universal

- Structure

- bridge

- Machined material

- for aluminum

Description

Press, Hold & Drill - Our solution to the incredible economic machining of parts in series production with a portal milling machine. On customer request here, even with a double spindle on a PFU-S 2010.

The operating principle:

1. The workpiece is pressed by a presser foot by 2 pneumatic cylinders from the top of the table. The holding force is here per kg at 30th The holding force is adjustable via pressure regulator.

2. The pressure foot, in which the suction device is integrated fixed, the workpiece on the table.

3. The aluminum plates are pierced. 20 pieces each 1.5 mm. The whole thing through the use of double spindle equal to two times in parallel.

Series production economically and easily. By the PFU-S portal milling machine with dual spindles of BZT. Press & Hold Drill!

Catalogs

No catalogs are available for this product.

See all of BZT Maschinenbau GmbH‘s catalogsRelated Searches

- CNC milling machine

- Vertical CNC milling machine

- 3-axis CNC milling machine

- Bridge CNC milling machine

- Swiveling-spindle CNC milling machine

- 5-axis CNC milling machine

- High-precision CNC milling machine

- Aluminum CNC milling machine

- Threading machine

- Boring milling machine

- Wood CNC milling machine

- CNC boring and milling center

- Composite CNC milling machine

- Horizontal boring milling machine

- Electric threading machine

- 4-axis boring and milling center

- Frame included CNC milling machine

- Rotating table boring and milling center

- CNC threading machine

- Orthopedic CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.