- Machine-tools

- Finishing Machine

- Vertical grinding machine

- C & B Machinery

- Products

- Catalogs

- News & Trends

- Exhibitions

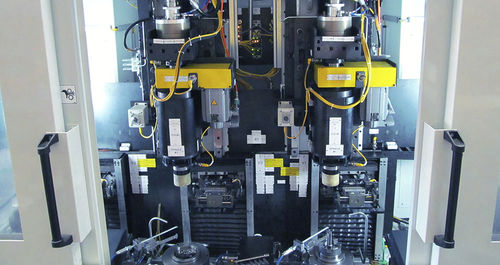

Vertical grinding machine CNCmulti-spindleprecision

Add to favorites

Compare this product

Characteristics

- Structure

- vertical

- Control type

- CNC

- Features

- multi-spindle

- Other characteristics

- precision, variable-speed

Description

Double spindle grinding machines can be used to either grind a part one side at a time or to grind 2 one-sided parts at a time. These machines are perfect for parts with a tight perpendicularity tolerance as well as parts that have un-equal stock removal. Stock removal is achieved through in-process gauging for maximum size control and repeatabilty.

Single spindle machines have a very small machine footprint, due to the vertical orientation of the spindle and the machine mounted electrical panel. This machine setup is perfect for parts that only require one side to be ground. By clamping on the bore or I.D./O.D. of the part we can ensure a tight squareness tolerance.

VIDEO

Related Searches

- Grinding machine

- CNC grinding machine

- Precision grinding machine

- Workpiece grinding machine

- Cylindrical grinding machine

- High-precision grinding machine

- Automated grinding machine

- Vertical grinding machine

- 3-axis grinding machine

- Stationary grinding machine

- High-productivity grinding machine

- Gear grinding machine

- Horizontal grinding machine

- Hydraulic grinding machine

- 2-axis grinding machine

- Crankshaft grinding machine

- Shaft grinding machine

- Multi-spindle grinding machine

- Variable-speed grinding machine

- 5-axis grinding machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.