- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

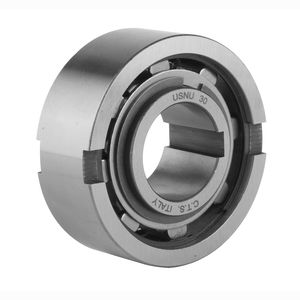

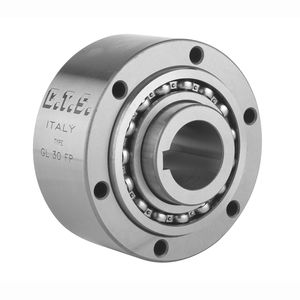

Sprag one-way clutch GLG serieswith internal bearingsindexingbackstop

Add to favorites

Compare this product

Characteristics

- Technology

- sprag

- Construction

- with internal bearings

- Applications

- backstop, overrunning clutch, indexing

- Other characteristics

- high-speed, irreversible

- Torque

Max.: 3,230 Nm

(2,382.3257 ft.lb)Min.: 210 Nm

(154.8881 ft.lb)- Diameter

Max.: 80 mm

(3.15 in)Min.: 25 mm

(0.98 in)- Rotational speed

Max.: 4,600 rpm

(28,902.65 rad.min-1)Min.: 700 rpm

(4,398.23 rad.min-1)

Description

The GLG Series freewheels are particularly suitable for applications requiring long operation times in neutral at high speeds. These have the same bodies as the GL series but a cage of the GP series is mounted inside which makes it possible for the bodies to detach when running in neutral to reduce wear. Flanges are from the GL series, see pages 32 to 37 for dimensions. Models with holes 70 and 80 are produced by modifying only the internal ring of the GLG60/GL2G60, for which the same kind of flanges are mounted. The torque forces are transmitted from the shaft to the inner race by means of a key and from the outer race to the external area by means of screws. Shaft tolerances must be h6, whilst tolerances for the driven part must be H7. Grease lubrication with a labyrinth seal allows a high reduction of heat due to oil movement and friction between sealing rings. Each freewheel is supplied with paper gaskets (without paper gaskets, the freewheel can be seriously damaged).

Catalogs

Related Searches

- One-way clutch with internal bearings

- Roller overrunning clutch

- Backstop backstop

- Indexing backstop

- Overrunning clutch backstop

- Sprag freewheel

- Bearing backstop

- Low-speed backstop

- Irreversible one-way clutch

- High-speed one-way clutch

- Freewheel cage

- Sprag freewheel cage

- Backstop freewheel cage

- Indexing freewheel cage

- Overrunning clutch freewheel cage

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.