- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

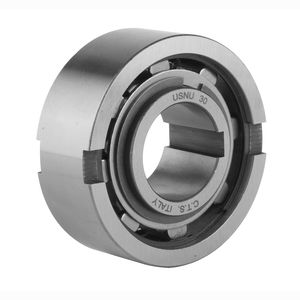

Sprag freewheel cage GM seriesindexingbackstopoverrunning clutch

Add to favorites

Compare this product

Characteristics

- Technology

- sprag

- Applications

- backstop, indexing, overrunning clutch

- Torque

Max.: 622 Nm

(458.7637 ft.lb)Min.: 3 Nm

(2.2127 ft.lb)- Diameter

Max.: 70 mm

(2.76 in)Min.: 4 mm

(0.16 in)- Rotational speed

Max.: 10,000 rpm

(62,831.85 rad.min-1)Min.: 1,500 rpm

(9,424.78 rad.min-1)

Description

the GM series.... is a cage with contact elements running

on a metric sized freewheel race.

the smaller dimensions and the high transmission torque offer some interesting technical and cost-saving solutions.

Fitting multiple cages side-by-side increases torques.

It is necessary to place one or two bearings next to the

freewheel so that the outer race can rotate centrally to the inner race.

When the sliding race is machined in the seats or on the shafts, the following specifications must be adhered to:

1) 60/62 hrc surface hardness

2) 1 mm minimum depth of tempering after grinding

3) ensure the concentric rotation of the races

4) lubrication suitable for the application.

Catalogs

Related Searches

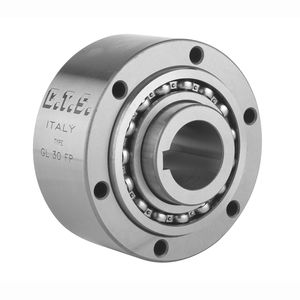

- One-way clutch with internal bearings

- Roller overrunning clutch

- Backstop backstop

- Indexing backstop

- Overrunning clutch backstop

- Sprag freewheel

- Bearing backstop

- Low-speed backstop

- Irreversible one-way clutch

- High-speed one-way clutch

- Freewheel cage

- Sprag freewheel cage

- Backstop freewheel cage

- Indexing freewheel cage

- Overrunning clutch freewheel cage

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.