- Food industry

- Other Food Machinery

- Air thawing machine

- Cabinplant A/S

Air thawing machine for fishmeatshrimp

Add to favorites

Compare this product

Characteristics

- Type

- air

- Food product

- for fish, meat, shrimp, fruit, vegetable

- Batch/continuous

- continuous

- Applications

- for the food industry

Description

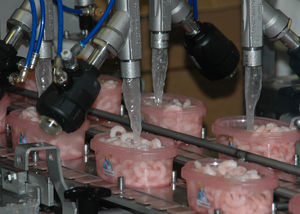

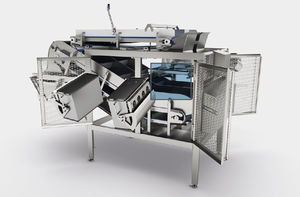

Cabinplant provides a belt thawing unit using temperate air for continuous defrosting of various types of IQF frozen products, such as shrimp (both cold and warm water), vegetables, etc. Capacities are up to 5 t/h, depending on kg/m³, layer thickness and belt speed.

The product is placed in an even layer on the belt and conveyed through the zones of the thawing unit, where fans direct a tempered air flow through belt/product. To prevent product dehydration the air is kept saturated through constant injection of water particles straight into the air flow. A thin film is formed on the product surface to protect and maintain quality. Each thawing zone of the machine incorporates separate temperature sensors and heat control. The belt speed is adjustable.

The unit consists of:

• Fans for air circulation

• Belt for product conveyance

• Nozzle system to ensure constant air moistening. Water is supplied direct from water main.

• CIP system with rotating nozzles to minimize bacteriological problems

• Large inspection hatches for optimum access to thawing zones (inspection and cleaning)

• Continuous belt cleaning system(optional)

Benefits

• Higher yield due to reduced drip loss

• Minimum water consumption

• Shorter thawing time

• Improved product quality, as no mechanical product handling or wash-out of nutrients occur

• Improved hygiene with reduced risk of acute, uncontrollable bacteriological problems, as the product is segregated.

Capacity

• Up to 5 t/h, depending on kg/m³, layer thickness and belt speed

Use

• Block-frozen products: Whole, small fish and/or deheaded fish

• IQF products: Fish, Shrimp, Meat, Vegetables, Fruit and berries

Catalogs

No catalogs are available for this product.

See all of Cabinplant A/S‘s catalogsRelated Searches

- Solid classifier

- Centrifugal classifier

- Sorting machine

- Classifier for the food industry

- Optical sorting machine

- Pasteurizer

- Automatic separator

- Food sorting machine

- Sorting machine for the food industry

- Pasteurizer for the food industry

- Gauging

- Depositor

- Bulk material separator

- Drum separator

- Blanching machine

- Continuous sorting machine

- Depositor for the food industry

- Mechanical grader

- Gauging with conveyor

- Fruits and vegetable blancher

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.