Automatic filler containertrayoil

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- container, tray

- Product applications

- oil, for viscous liquids, sauce, for pasty products

- Domain

- for the food industry

- Type

- piston, pneumatic, servo-driven

- Number of heads

- three-head

- Volume

2 l

(0.5 gal)

Description

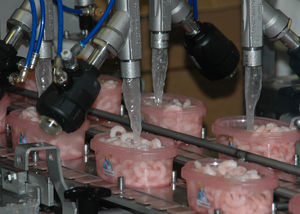

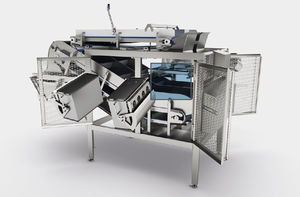

Cabinplant automatic piston fillers are designed for fast and accurate filling of liquids, matching required capacity, viscosity and filling volume. The filling valves can be fixed or mounted to follow the packing material for a higher capacity.

The fillers are designed to match required capacity, viscosity and filling volume. Advantages include:

• Recipe control to ensure swift production change-over

• Specially designed filling heads with cut-off system to prevent drip and spillage

• Even distribution of liquid across the product in e.g trays

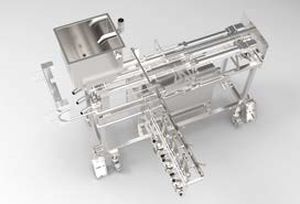

The piston filler consists of stainless steel hopper with removable cover and sensor for detection of product level in tank. The hopper can be equipped with one rotary agitator for product mixing at your option.

The piston filler is fitted either with a pneumatic cylinder (fully automatic piston filler) or a servo-operated spindle motor (fully electronic double piston filler). A servo-operated spindle motor ensures optimum liquid handling.

The piston filler can be provided either as an individual machine or as part of a complete processing line, e.g. a ready-meal line.

The special design of Cabinplant piston fillers ensures easy and safe cleaning and meets the high cleaning demands of the food industry. Product wetted parts can be dismantled without the use of tools for thorough cleaning and sterilization.

Benefits

• Accurate filling

• “No can - No fill” system

• Reduced give-way

• Easy cleaning

• Low maintenance

Capacity

• The filling volume is up to 2 litres each filling. Capacity depends on product viscosity and quantity.

Use

• Sauce

• Oil and brine

• Marinade

• Soup

• Mayonnaise

Catalogs

No catalogs are available for this product.

See all of Cabinplant A/S‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Filler for the food industry

- Food product filling machine

- Volumetric filler

- Multi-head filler

- Complete packaging line

- Container filler

- Piston filler

- Automatic complete packaging line

- Compact filler

- High-speed filler

- Can filler

- Rotary filler

- PET bottle filling machine

- Sauce filler

- Oil filler

- Jar filler

- Pasty product filler

- Pneumatic filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.