Immersion thawing machine for fishshrimpcontinuous

Add to favorites

Compare this product

Characteristics

- Type

- immersion

- Food product

- for fish, shrimp

- Batch/continuous

- continuous

- Applications

- for the food industry

Description

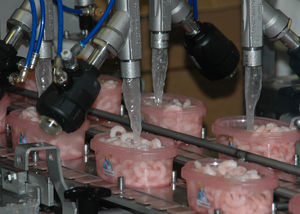

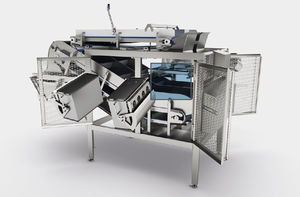

Cabinplant can provide a continuous thawing unit using submersion for automatic defrosting of IQF products, such as shrimp (cold and warm water), lobster, etc. The product is submerged in a water bath and thawed by means of recirculated water. The thawed product falls off the block and sinks to the bottom where a water flume conveys it to the discharge elevator. On the discharge elevator the product is separated from the water and discharged onto an inspection conveyor or similar equipment.

The product is submerged into a water bath and defrosted during conveyance. A flume cascading water across the entire thawing belt secures product defrosting in counterflow during conveyance. This way the hottest water reaches the coldest product at the infeed end, and the temperature at the discharge end is kept as low as possible.

The unit consists of:

• Modular plastic belt

• Accumulation vessel for thawing water

• Water distribution system

Benefits

• Rapid thawing time

• Low investment

• Continuous thawing, even of block-frozen products

• Low product temperature at outlet

Capacity

• 600-1200 kg/h

Use

• Block-frozen products: Whole, small fish and/or deheaded fish.

• IQF products: Shrimp, Lobster

Catalogs

No catalogs are available for this product.

See all of Cabinplant A/S‘s catalogsRelated Searches

- Solid classifier

- Centrifugal classifier

- Sorting machine

- Classifier for the food industry

- Optical sorting machine

- Pasteurizer

- Automatic separator

- Food sorting machine

- Sorting machine for the food industry

- Pasteurizer for the food industry

- Gauging

- Depositor

- Bulk material separator

- Drum separator

- Blanching machine

- Continuous sorting machine

- Depositor for the food industry

- Mechanical grader

- Gauging with conveyor

- Fruits and vegetable blancher

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.