- Food industry

- Fish Processing

- Mackerel processing line

- Cabinplant A/S

Mackerel processing line

Add to favorites

Compare this product

Characteristics

- Fish type

- for mackerel

- Throughput

270 p/min

Description

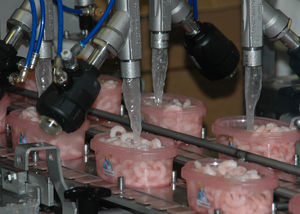

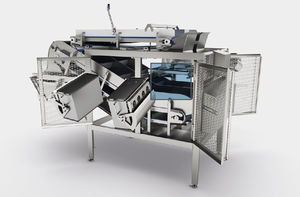

Our large capacity mackerel processing line has been designed for a continuous and automated production flow. Our mackerel line is developed to cover all processes from preparation, processing, and packing into cans. The existing equipment to match your requirements.

We provide complete solutions for processing of mackerel from both temperate and tropical seas. We have solutions for frozen mackerel, fresh mackerel, and mackerel in cans, typically club cans; but also 1/4 P-long cans.

Our solutions for canned mackerel include infeed, grading, deheading, gutting, removal of skin, cooking, manual filleting, canning, check weighing, addition of liquids, seaming, washing, sterilizing in autoclave, and packing.

Benefits

• Higher yield

• Low production costs

• Accurate adjustment of cooking/ cooling temerature

• Large capacity

• Modular design

• Continuous production flow

• Hygienic and easy-to-clean design

• Low water consumption

Capacity

• Up to 270 cans/minute

Use

• IQF mackerels

• Fresh mackerels

• Addition of oil, tomato

VIDEO

Catalogs

No catalogs are available for this product.

See all of Cabinplant A/S‘s catalogsRelated Searches

- Steam cooking unit

- Fish skinning machine

- Brine injector machine

- Automatic fish skinning machine

- Continuous cooking unit

- Batch industrial cooker

- Vegetable industrial cooker

- Boiling industrial cooker

- Fish scaling machine

- Industrial cooker with cooler

- Shellfish industrial cooker

- Fish industrial cooker

- Fish processing line

- Heading gutting machines

- Rice industrial cooker

- Cheese brine injector machine

- Shellfish processing line

- Shrimp industrial cooker

- Large industrial cooker

- Mackerel fish skinning machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.