Automatic fish skinning machine for mackerel

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Fish type

- for mackerel

Description

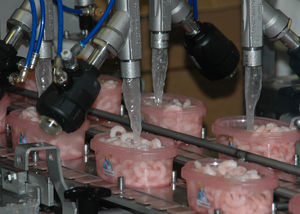

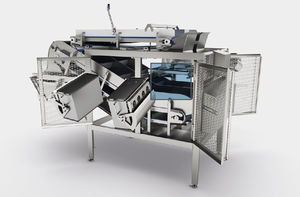

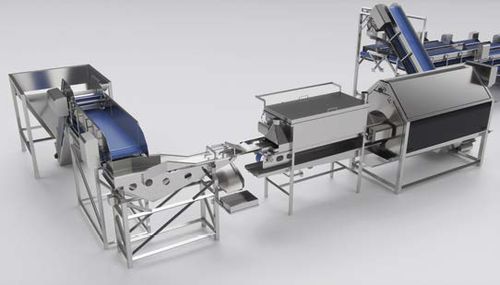

The complete line is used for deskinning of mackerel before cooking and cutting - primarily to be filled in club or P-long cans. Individual IQF mackerels are introduced to the line where hot water is sprayed on the product to make the skin split and loosen. Subsequently a specially designed tumbler deskins the mackerel - all in one continuous process.

The entire process is controlled from one master control panel for adjustment of for instance time and temperature.

In an age of declining fish stocks and fishing quotas, raw seafood is an increasingly valuable commodity. Even small amounts of excess waste can have a dismal effect on your bottom line. Cabinplant specializes in developing processing lines that minimize waste through gentle and optimal treatment of raw material. We also have in-depth experience with designing and manufacturing highly efficient plants that can reliably process large quantities rapidly and consistently. Gentle handling, efficient workflow, improved reliability: they all add up to higher yields.

Benefits

• Deskinning without the use of chemicals

• Limited amount of wastewater

• Only 5% product loss

• Low use of operators

• No disposal of hazardous fluids

• One continuous process

• Packing in cans increases productivity

Capacity

• 2500 kg/h

Use

• North mackerel (scomber scombrus)

Catalogs

No catalogs are available for this product.

See all of Cabinplant A/S‘s catalogsRelated Searches

- Steam cooking unit

- Fish skinning machine

- Brine injector machine

- Automatic fish skinning machine

- Continuous cooking unit

- Batch industrial cooker

- Vegetable industrial cooker

- Boiling industrial cooker

- Fish scaling machine

- Industrial cooker with cooler

- Shellfish industrial cooker

- Fish industrial cooker

- Fish processing line

- Heading gutting machines

- Rice industrial cooker

- Cheese brine injector machine

- Shellfish processing line

- Shrimp industrial cooker

- Large industrial cooker

- Mackerel fish skinning machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.