Semi-automatic packaging line for the food industryfor fishfilling

Add to favorites

Compare this product

Characteristics

- Application domain

- for the food industry

- Product applications

- for fish, filling

- Other characteristics

- semi-automatic

- Throughput

Max.: 35 p/min

Min.: 25 p/min

Description

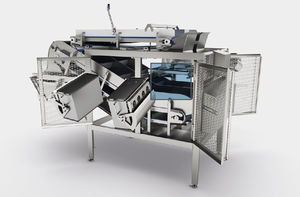

The Cabinplant semiautomatic packing system is designed for the filling of mackerel meat into Dingley, Club or 1/4 P Long cans.

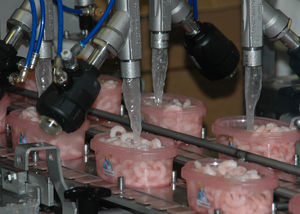

Cooked and cooled fish are conveyed to the packing machine on a conveyor belt, from where the operator takes the fish, cuts a fillet, and places the meat in a packing chain. The waste is discharged under the machine during filletting.

The packing chain is a specially designed plastic belt with pockets, which fit into a specific can size. The chain is turned upside down during processing, and the meat drops into a can placed underneath the chain. To secure the correct amount of meat in each can, the meat is pressed into the packing chain and then cut with a rotating knife between each pocket. This ensures that the meat fits exactly into the cans.

The semiautomatic packing machine is equipped with:

• Product belt for cooked/cooled product

• One cutting table per operator mounted with a waste chute

• Packing chain for meat divided into pockets

• Pressing wheel for meat in packing chain

• Knife for cutting meat in packing chain

• Transfer system for meat and cans

• Check weigher with reject system for overweight/underweight cans

Benefits

• Higher yield

• Low production costs

• High capacities

• Continuous production flow

Capacity

• Capacity per operator: 25-35 cans/min (club cans)

•

Use

• Mackerel

Catalogs

No catalogs are available for this product.

See all of Cabinplant A/S‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Filler for the food industry

- Food product filling machine

- Volumetric filler

- Multi-head filler

- Complete packaging line

- Container filler

- Piston filler

- Automatic complete packaging line

- Compact filler

- High-speed filler

- Can filler

- Rotary filler

- PET bottle filling machine

- Sauce filler

- Oil filler

- Jar filler

- Pasty product filler

- Pneumatic filling system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.