Sorting system for the food industry opticalfor conveyorfor fish

Add to favorites

Compare this product

Characteristics

- Application domain

- for the food industry

- Type

- optical

- Product applications

- for conveyor, for fish

- Other characteristics

- continuous

- Throughput

320 p/min

Description

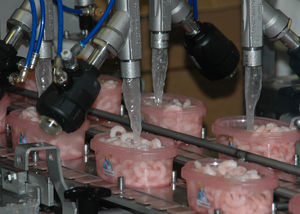

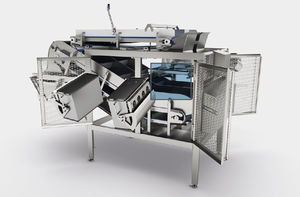

Camera-operated fish sorting system for existing filleting line: The Cabinplant vision system is designed for the surveillance of product infeed to Baader or VMK filleting machines. The system can be used for species such as herring and mackerel. The vision system controls the entire filleting machine, which means that it checks input and output - what goes in, comes out.

If not, the line will stop! The vision system will also try to optimize the amount of fish on the pocket conveyor belonging to the filleting machine. For instance if fish block the feeder to the filleting machine, the outlet gates of the feeder will be opened.

Fast and efficient

The system operates by taking a picture of each fish to determine if it is the right species, the right size, whole or half fish, and whether it has been placed correctly on the conveyor prior to cutting, etc. Unwanted fish are rejected to waste or recirculated in the system if it was rejected due to incorrect positioning on the conveyor.

Option: In addition, the vision system can be provided with a dry feeding conveyor to increase feeding efficiency to the filleting machine.

Benefits

• Reduction of the number of operators

• Increased output with correctly adjusted feeding unit

• Existing filleting machine set-up can be used

• Full statistics function on every piece

• PC-based control enables software upgrade

• Switch between production of herring and mackerel

Capacity

• Capacity 320 conveyor pockets/min

Use

• Herring

• Mackerel

Catalogs

No catalogs are available for this product.

See all of Cabinplant A/S‘s catalogsRelated Searches

- Rail conveyor

- Belt conveyor

- Conveyor for the food industry

- Sorting machine

- Food conveyor

- Optical sorting machine

- Curved rail conveyor

- Weigher

- Food sorting machine

- Sorting machine for the food industry

- Straight conveyor

- Weigher for the food industry

- Feeding unit

- Multihead weigher

- Automatic weigher

- Custom-made conveyor

- Trough conveyor

- Meat conveyor

- Continuous sorting machine

- Modular belt conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.