- Food industry

- Fish Processing

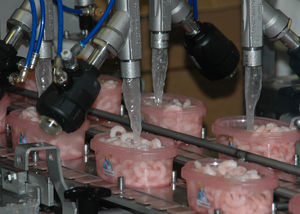

- Shrimp processing line

- Cabinplant A/S

Shrimp processing line inspectionchillingweighing

Add to favorites

Compare this product

Characteristics

- Shellfish type

- shrimp

- Operations

- chilling, inspection, weighing, canning, cleaning

Description

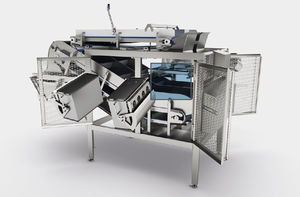

Cabinplant has more than 40 years of experience in supplying modular construction processing lines for virtually all types of commercial fish and shellfish. We deliver and install our lines all over the world.

Cabinplant can supply complete processing lines for farmed warm water shrimp.

A typical process flow of our processing line for warm-water shrimp is described below.

• Reception of raw material. Shrimp from the ponds are discharged into a bulk feeder with chilled water (first in-first out).

• Infeed to operators on deheading lines. The shrimp are weighed, filled into plastic trays and automatically covered with ice.

• Manual de-heading on belt system designed for improved flow of both product and waste.

• Grading of HSO (headless shell-on) followed by manual inspection.

• Manual peeling.

• Cooking by steam, either on a conveyor belt or by placing the shrimp in steel trays.

• Chilling with water.

• Freezing, either in blocks or IQF.

• Glazing to protect the surface against oxidisation.

• "Hardening" to secure the glaze.

• Weighing and packing into bulk (bags or carton boxes) or retail packaging, e.g. bags, trays, etc.

Benefits

• High yield

• Modular construction

• Gentle handling of product

• Few operators

• Hygienic design

• Integrated cooking and cooling

• High capacity

Capacity

• 500 to 4000 kg/h

Use

• Warm water shrimp

Catalogs

No catalogs are available for this product.

See all of Cabinplant A/S‘s catalogsRelated Searches

- Steam cooking unit

- Fish skinning machine

- Brine injector machine

- Automatic fish skinning machine

- Continuous cooking unit

- Batch industrial cooker

- Vegetable industrial cooker

- Boiling industrial cooker

- Fish scaling machine

- Industrial cooker with cooler

- Shellfish industrial cooker

- Fish industrial cooker

- Fish processing line

- Heading gutting machines

- Rice industrial cooker

- Cheese brine injector machine

- Shellfish processing line

- Shrimp industrial cooker

- Large industrial cooker

- Mackerel fish skinning machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.