- Food industry

- Fish Processing

- Shrimp processing line

- Cabinplant A/S

Shrimp processing line inspectionchillingweighing

Add to favorites

Compare this product

Characteristics

- Shellfish type

- shrimp

- Operations

- inspection, weighing, chilling, freshwater cooking, cleaning

Description

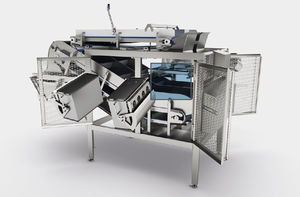

Cold water shrimp are much smaller than their tropical cousins, and are generally considered more flavourful than warm water varieties. We provide complete lines for the processing of cold water shrimp with a wide range of capacities.

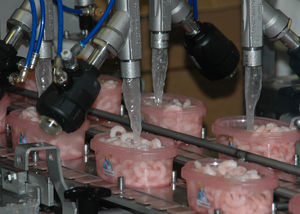

are performed in the pick-and-place operation during which a robot transfers individual products from a feeding conveyor into the package.

We can help you make the right choice and manufacture a processing line to suit your requirements. All our processing lines are assembled and tested in our factory prior to delivery.

A typical processing line comprises:

• Reception of raw material, either blockfrozen or fresh in boxes covered with ice

• Frozen blocks are thawed, fresh product is de-iced.

• Grading, typically into three sizes

• Mixing with a special salt brine followed by cold storage (maturing to ease automatic removal of shells)

• Emptying into a bulk feeder, storage vessels are washed.

• Cooking

• Chilling by means of water prior to distribution to peeling machines. Infeed is controlled by a batch weighing unit.

• Cleaning by means of flow separators, scanners, manual inspection etc.

• Freezing

• Grading, typically into five sizes to optimise glazing

• Glazing

• "Hardening" to secure the glaze

• After-freezing

• Weighing and bulk packing (bags or carton boxes) or retail packaging, e.g. bags, buckets etc.

Benefits

• High yield

• Modular construction

• Gentle handling of product

• Few operators

• Hygienic design

• Integrated cooking and cooling

• High capacity

Catalogs

No catalogs are available for this product.

See all of Cabinplant A/S‘s catalogsRelated Searches

- Steam cooking unit

- Fish skinning machine

- Brine injector machine

- Automatic fish skinning machine

- Continuous cooking unit

- Batch industrial cooker

- Vegetable industrial cooker

- Boiling industrial cooker

- Fish scaling machine

- Industrial cooker with cooler

- Shellfish industrial cooker

- Fish industrial cooker

- Fish processing line

- Heading gutting machines

- Rice industrial cooker

- Cheese brine injector machine

- Shellfish processing line

- Shrimp industrial cooker

- Large industrial cooker

- Mackerel fish skinning machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.