- Food industry

- Fish Processing

- Herring fish scaling machine

- Cabinplant A/S

Herring fish gilling machine

Add to favorites

Compare this product

Characteristics

- Fish type

- for herring

- Output-

270 p/min

Description

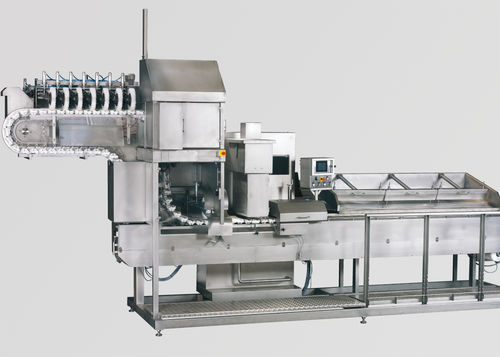

Our gilling machine is designed to remove the gills from herring prior to their storage/marinating in barrels and subsequent consumption To ensure the correct cut, the positioning of gills is controlled by vision technology. The gills are cut loose and removed by means of vacuum. Part of the guts can also be removed in this process.

After gilling, the fish is graded into seven sizes already determined by the vision system prior to gilling. Undersized herrings are discharged before entering the cutting system.

Cabinplant can provide complete herring processing lines with capacities up to 70-80 tons per hour. The gilling machine consists of:

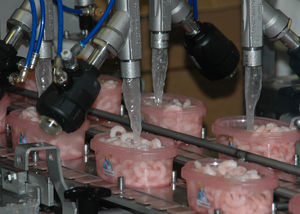

• Conveyor belt with specially designed plastic pockets in which the fish is placed

• Manual infeed section with platform and accumulation tray

• Vision system to determine the position of the gills and the size of the fish

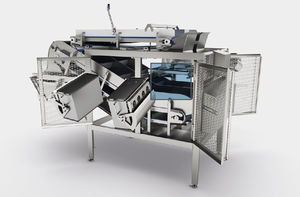

• Reject system for undersized fish

• Cutting/drilling and vacuum system to remove the gills

• Distribution system for seven grades

The gilling machine can be manually fed by up to 3 operators, or automatically by a Swede Fish AP12 feeder.

Benefits

• High capacity

• Integrated sorting

• Optional reject of foreign species

• High-quality treated product

• Low expenditure

• Food-grade materials

Capacity

• 270 fish/min

Use

• Herring

Catalogs

No catalogs are available for this product.

See all of Cabinplant A/S‘s catalogsRelated Searches

- Steam cooking unit

- Fish skinning machine

- Brine injector machine

- Automatic fish skinning machine

- Continuous cooking unit

- Batch industrial cooker

- Vegetable industrial cooker

- Boiling industrial cooker

- Fish scaling machine

- Industrial cooker with cooler

- Shellfish industrial cooker

- Fish industrial cooker

- Fish processing line

- Heading gutting machines

- Rice industrial cooker

- Cheese brine injector machine

- Shellfish processing line

- Shrimp industrial cooker

- Large industrial cooker

- Mackerel fish skinning machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.