•Designed for forming gas applications, particularly those in metal heat treating

•Ultra O2 measurement down to 10E-30ppm allow for extreme temperatures

•Thermodynamic H2O dewpoint

•Alarm relay circuits for a complete monitoring solution

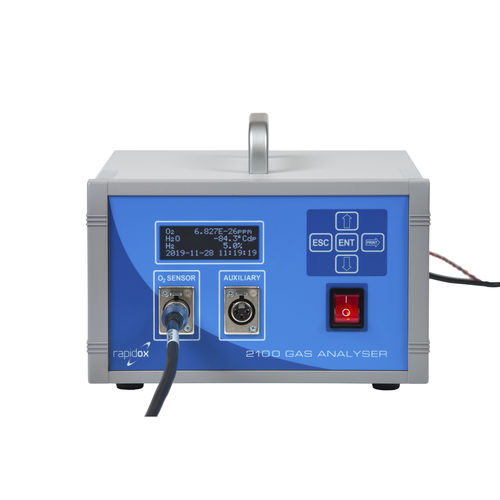

•OLED display (20 x 4 characters) for clear visibility from all vantage points

•Verified at Cambridge University by a thermodynamics expert; cementing the quality of the Rapidox 2100-FGA

•Easy user calibration procedure for after-sale longevity

•Pre-calibrated sensor enables the user to swap over locally without the aid of a PC – we call it ‘hot swap sensor’.

•Type K thermocouple (0-1250°C)

•0-5V and 4-20mA

•Installed with Modbus RTU language protocol for a complete communications and data-logging experience

•Pin code protection for extra security