Blowout preventers (BOP) control system CLC seriesnitrogenATEXonshore

Add to favorites

Compare this product

Characteristics

- Product applications

- for blowout preventers (BOP), nitrogen

- Other characteristics

- ATEX, onshore

Description

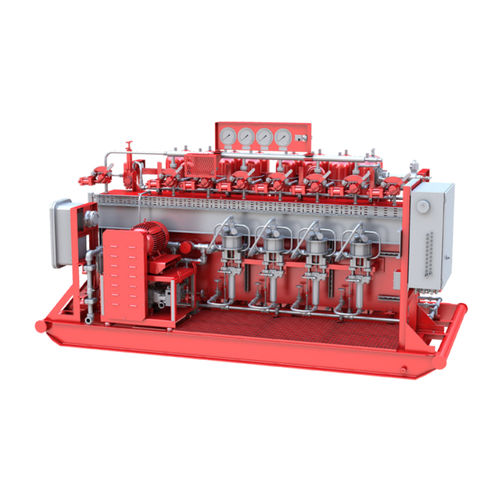

As a crucial component of well control, Cameron land closing units are built to high quality standards

and meet API 16D requirements. The land closing units use precharged nitrogen bladder accumulator

bottles, hydraulic fluid, and electric- and air-based pumps to generate pressure to operate multiple

functions on a BOP stack. Remote panels are offered in electric PLC touch screen, electric PLC push

button, or pneumatic air-based remote options.

Cameron offers standard system designs that complement our ram-type BOPs and also custom-

engineered designs. Our standard designs include industry-leading layouts that improve the safety

and serviceability of our land closing units.

BENEFITS

■ Improved safety and serviceability with industry-leading layouts and field-tested components

■ Systems that can be designed and manufactured to meet all major companies’ specifications, including API 16D, ATEX, and all European directives

■ Servicing options available in the US, Canada, South America, and internationally

FEATURES

■ Designed and manufactured per API 16D

■ Low-pressure alarm available

■ Triple redundancy

■ Standardized components

■ Modular design for simple configurability

■ Several available skid designs

■ High-quality programmable logic control (PLC) components that minimize the potential for compatibility issues with rig electronics by working with most PLC manufacturers’ control equipment

■ Touchscreen PLC, push-button hardwire PLC, and pneumatic remote options available

■ Optional Class 1. Div.1, ATEX, and other safe-area offerings

■ Available API 16D monogram

Catalogs

No catalogs are available for this product.

See all of CAMERON‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.