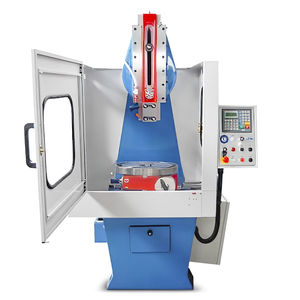

NC slotting machine 300 3AC3-axisrotating table

Add to favorites

Compare this product

Characteristics

- Control type

- NC

- Number of axes

- 3-axis

- Options

- rotating table

Description

Automatic longitudinal and horizontal pre-programmed and reversible slot machining and automatic rotation of turntable for any required slot depth and diameter.

Tool lift obtained by alternating table movements.

Once the pre-programmed slot depth has been reached, in automatic the machine performs a number of finishing strokes and the ram stops in its top position and the workpiece table in automatic returns to machining start cycle position.

Electronic turntable with central through hole to floor with possibility of programming 1500 symmetrical and 999 asymmetrical divisions.

Possibility of machining specific trapezoidal, circular and linear slots.

The incorporated NC technology provides a user friendly operator/machine interface, the operator can call up data on the display utilising the keypad, enter production data.

The type of technology incorporated is easy and simple to use.

Machining programmes with zero workpiece position can be saved and stored and called up when required.

It is possible to store up to 100 programmes.

This model can run in automatic two or more programmes in sequence.

The software offers the following standard applications:

• slot bottom finishing: in the event the slot is widened the operator has the possibility of milling the bottom of the slot to finish.

• incremental tool lift: with this function enabled the tool is completely raised out of the slot when the ram returns and returns to zero workpiece position.

If required, it is possible to add and incorporate specific software functions and applications:

Catalogs

No catalogs are available for this product.

See all of CAMS srl‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.